Mitsubishi Electric Laser Processing Machine Automatic Sorting System

From material delivery to sorting, the laser production process is fully automated! Automatically selecting the appropriate tools according to the purpose.

We would like to introduce the "Mitsubishi Electric Laser Processing Machine Automatic Sorting System," which has achieved complete automation of a series of production processes, including material input, laser processing, sorting, removal of scrap materials, and loading of finished products. This system enables all-day operation, significantly improving the productivity of the entire laser process. Additionally, it contributes to the reduction of costs and human errors caused by manual work. By changing the tools at the end of the arm, it can accommodate a wide range of sorting shapes and automatically select the appropriate tool based on information such as the material, shape, and weight of the components. 【Features】 - Complete automation of the laser production process from material input to sorting - Automatic selection of appropriate tools based on purpose - Long continuous operation enabled by shelf specifications - Wide adaptability with independently controlled four arms - Intuitive operation with a dedicated sorting CAM included as standard, allowing program completion in four clicks *For more details, please download the PDF or feel free to contact us.

basic information

【Standard Tool Set】 ■Vacuum Suction Tool (Single) ■Vacuum Suction Tool (Multiple) ■Magnet Tool *For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

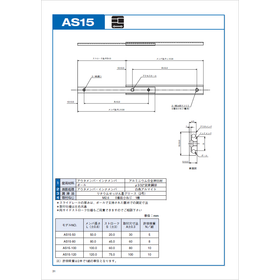

catalog(1)

Download All CatalogsRecommended products

Distributors

Since our establishment in 1947, we have steadily built our achievements as a comprehensive trading company for FA equipment and power transmission components. We are deeply grateful for the support we have received from all of you. In the high-tech machinery industry, the technical demands for further automation, labor-saving, and IT integration are becoming increasingly sophisticated and diverse every day. In this context, we believe it is our mission to contribute to global manufacturing by swiftly procuring and fulfilling the industrial products required by the times. Going forward, we will continue to strive to provide high-value-added services that meet our customers' expectations and requests, guided by the principles of service and sincerity. We sincerely ask for your continued patronage in the future.