Introduction of Composite Repair Cases (Power Plants)

Introduction of Composite Repair Cases (Power Plants)

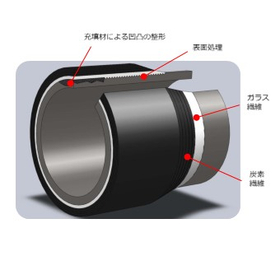

Due to welding dissimilar metals to the tee joint, we observed wall thinning at the weld seam and water leakage from the through holes due to galvanic corrosion. To reduce the progression of wall thinning and the risk of fracture, we adopted our composite repair. Based on strength calculations according to ISO 24817, we calculated the number of layers required to suppress water leakage at the time of fracture, assuming that the entire circumference of the weld seam would fracture. Thanks to the flexible sheet-like carbon fiber woven in four directions, it can be applied not only to straight pipes but also to complex shapes of piping and equipment, such as tee joints. Furthermore, the repair layer is very lightweight, so there is no need to install additional support for the piping. With our composite repair, we were able to reduce the risk of human injury and the risk of unexpected shutdowns at the power plant.

1~3 item / All 3 items

-

Long-term extension of meat reduction piping with 'Composite Repair' *Presentation of construction case materials

Repairs are made according to the necessary durability years and purpose (strength restoration, leak prevention, corrosion protection). It allows for predicting maintenance timing and is suitable for permanent plant maintenance!

last updated

-

[Composite Repair Case Study] Fire Hydrant Reduced Thickness Pipe Penetration and Leak Repair

Composite materials made of carbon fiber and epoxy resin to avoid the risk of pipe bursts and unexpected shutdowns at power plants! *Examples of construction at thermal power plants are introduced with photos.

last updated

-

【Basic Knowledge Material】What is Composite Repair?

We introduce the design, quality, and history of the development of composite repairs!

last updated