Hexacore Inc. | Solving your visualization and communication equipment problems

We contribute to the development of an information and communication society with solutions that support the safety and efficiency of power supply.

Hexacore Co., Ltd. is a manufacturer based in Natori City, Miyagi Prefecture, specializing in the design, manufacturing, and sales of communication buildings, data centers, and measurement and monitoring systems. 【Business Overview】 - Design, manufacturing, and sales of power distribution boards for various telecommunications operators - Design, manufacturing, and sales of remote monitoring systems (sensors and manager software), etc. 【Our Features】 - We respond flexibly to customer requests, from specification changes of existing products to fully customized orders. - With a production system that prioritizes safety, you can trust us with aftercare as well. - We engage in "monozukuri" (manufacturing) utilizing our wisdom and unique technological capabilities, having received numerous patents and awards. For any concerns or issues related to visualization and communication equipment, please leave it to "Hexacore."

basic information

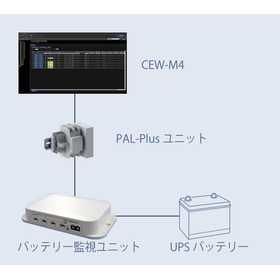

【Industry-Specific Solutions (Partial)】 ■ Services for Telecommunications Operators - Intermediate Current Supply Device: DC-48V Direct Current Distribution Board - Rectifier Rack-Mounted Expansion Direct Current Distribution Board: Distribution Board for Small Box Buildings | We are also actively proposing VE and VA solutions | ■ Services for Data Center Operators - SVU-ST: AC Distribution Board adopting a patented structure - PDU-series: AC Distribution Boards for Data Centers | We also support commissioning tests and more | ■ Monitoring Systems - PAL-Plus: AC Current Sensor with Built-in Communication Function - PAL-Temp: Inexpensive, Compact, and Easy-to-Install Temperature and Humidity Sensor - CEW-M4: Manager Software that Contributes to Energy Saving | Recommended for those who want to "visualize first" | In addition, we offer a variety of products. For more details, please refer to the PDF materials or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

【Achievements (Partial)】(In no particular order, titles omitted) ■ Alarm Monitor System (Gakushuin Educational Institution) ■ Remote Power Cut-off Receiving Unit (NTT East Corporation) ■ Variable Expansion Receiving Unit (NTT East Corporation) ■ PDU・PDP (NTT Facilities, Inc.) ■ Remote Monitoring System CEW-M4 (Marunouchi Direct Access, Inc.) ■ HVDC-MCCB-PDF (NTT Facilities, Inc.) and more Examples of Hexacore products that have been implemented and testimonials from our customers are available on our company website, so please take a look.

Related Videos

catalog(11)

Download All CatalogsRecommended products

Distributors

Company profile: Hexacore Inc. designs, manufactures and sells telecommunications and data centre equipment, as well as measurement and monitoring systems. In a world moving towards sustainability, telecommunications and energy infrastructure remain essential to our daily lives. Hexacore offers solutions that support the construction of safe and efficient communication facilities, promoting energy efficiency and backed by technical expertise and a customer-oriented support system. Notice: Please note that, effective 1 April 2023, our company name was changed from Chuo Seisakusho Co., Ltd. to Hexacore Inc.