| Hexacore Factory Introduction | Manufacturer of Distribution Boards and IoT Sensors

We will introduce the environment in which our products are made, showcasing the Hexacore headquarters and factory.

Hexacore Inc. is a manufacturer based in Natori City, Miyagi Prefecture, specializing in the design, manufacturing, and sales of equipment for communication buildings and data centers, as well as measurement and monitoring systems. Here, we introduce the Hexacore factory, which serves as the design and manufacturing base for our products. 【Features】 - Adoption of bright and energy-efficient LED lighting - Improvement of safety by developing our own manufacturing and inspection jigs related to product creation - Assurance of product safety through progress management and QC process management using our proprietary software |You can view more details in the video!| 【For those considering product introduction】 We welcome factory tours (in Natori City, Miyagi Prefecture). You can check the actual equipment and directly observe the manufacturing environment of our products, including the manufacturing process. If you are interested, please feel free to contact us.

basic information

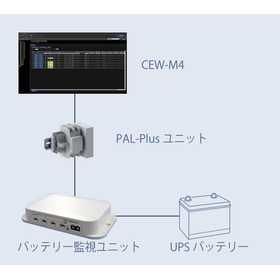

【Industry-Specific Solutions】 ■ Measurement and Monitoring Systems - AC current sensor with built-in communication function: PAL-Plus - Inexpensive, compact, and easy-to-install temperature and humidity sensor: PAL-Temp - Energy-saving management software: CEW-M4, etc. |Recommended for those who want to start with "visualization"| ■ Services for Telecommunications Operators - DC distribution board for DC-48V: Intermediate current supply device - Products for small box buildings: Rectifier-mounted expansion DC distribution board - Products for base stations: Optical power integrated panel, optical terminal box, etc. |We actively propose VE and VA solutions as well| ■ Services for Data Center Operators - Patented AC distribution board: SVU-ST - AC distribution board for data centers: PDU-series, etc. |We also support commissioning tests and more| In addition, we offer a variety of products, so please check the Ipros product page for details or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

【Achievements/Case Studies】(In no particular order, titles omitted) - Alarm Monitoring System (Gakushuin Educational Institution) - Remote Power Cut-Off Receiving Unit (Nippon Telegraph and Telephone East Corporation) - Variable Expansion Receiving Unit (Nippon Telegraph and Telephone East Corporation) - PDU・PDP (NTT Facilities, Inc.) - Remote Monitoring System CEW-M4 (Marunouchi Direct Access Co., Ltd.) - HVDC-MCCB-PDF (NTT Facilities, Inc.) and others Examples of Hexacore products that have been implemented and feedback from our customers are available on our company website, so please take a look.

Related Videos

catalog(11)

Download All CatalogsRecommended products

Distributors

Company profile: Hexacore Inc. designs, manufactures and sells telecommunications and data centre equipment, as well as measurement and monitoring systems. In a world moving towards sustainability, telecommunications and energy infrastructure remain essential to our daily lives. Hexacore offers solutions that support the construction of safe and efficient communication facilities, promoting energy efficiency and backed by technical expertise and a customer-oriented support system. Notice: Please note that, effective 1 April 2023, our company name was changed from Chuo Seisakusho Co., Ltd. to Hexacore Inc.