Deep hole machining of small diameter for medical devices.

Precision machining of small-diameter deep holes in titanium and medical stainless steel! Drilling straight deep holes.

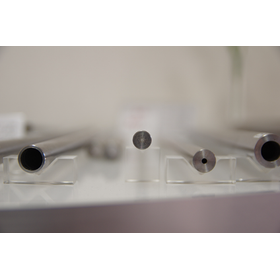

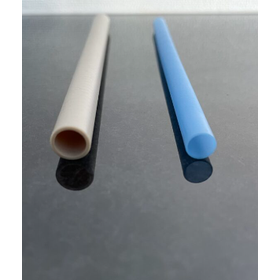

We would like to introduce our "small-diameter deep hole machining for medical devices." Our Gundrill machine is specially designed to handle high-difficulty machining applications and medical and dental components. We provide excellent precision and outstanding surface finish even for difficult-to-machine materials such as titanium and medical stainless steel. [Features] - Main materials: β-titanium, nickel-titanium, etc. - Capable of drilling holes in workpieces that have been machined to shape. *For more details, please download the PDF or feel free to contact us.

basic information

【Orthopedic Surgical Instruments】 ■ Crown Reamer φ1.8–4 Depth 300L ■ Step Reamer φ3.5 Depth 474L ■ Lag Screw Reamer φ3.1 Depth 315L ■ Implant * For joining fractured parts, etc. ■ Nail φ2–4.6 Depth 260L ■ Screw φ1.6–3.2 Depth 100L * For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

Haitak boasts industry-leading contract gun drilling processing technology, catering to a wide range of industries including medical, aerospace, automotive, and semiconductors. Our in-house developed gun drilling machines are equipped with high rotational precision and built-in servo spindles, enabling deep hole processing exceeding L/D200. By manufacturing over 1,000 types of gun drills and special jigs in-house, we meet all customer needs. From small diameter to large-scale operations, we contribute to solving customer problems with precision and speed. Our machines, equipped with unique technology and international patents, excel in reliability and cost performance, making them the optimal choice for engineers. Haitak resolves all challenges in deep hole processing and provides complete satisfaction to our customers.