深孔加工/ガンドリル加工

深孔加工/ガンドリル加工

医療分野だけでも50社以上、外形加工済のワークや、要求同芯度Φ0.05など非常に難度の高い加工に対応しており、医療工具・自動車部品・工具部品・各種スリーブピン・コアピン・金型冷却穴・スピンドル軸 など多種多様な 深穴加工実績があります。 Φ0.5~Φ30まで加工径に対応する専用スピンドルモータ を開発し、各径専用のガンドリルマシンを多数取り揃えているために、加工の品質を高める事ができ皆様からのコストダウンや短納期のご要望にお応えしています。

1~17 item / All 17 items

-

Gun drill deep hole machining service

We can accommodate requests for cost reduction and short delivery times with deep hole drilling using a gun drill!

last updated

-

Deep hole machining of small diameter for medical devices.

Precision machining of small-diameter deep holes in titanium and medical stainless steel! Drilling straight deep holes.

last updated

-

Deep hole machining for automotive parts

In the automotive parts production line, efficient tools are essential for enhancing profitability!

last updated

-

Deep hole machining for aerospace (difficult-to-cut materials)

High-quality main spindle motors contribute to the high precision required for aerospace components!

last updated

-

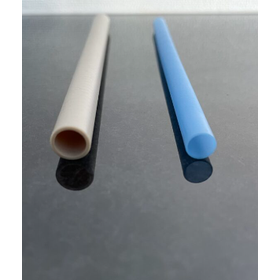

Deep hole machining of resin

Work hours can be reduced! Achieving both cost reduction and excellent finishing.

last updated

-

The world's smallest class in gun drilling! Deep hole machining from φ0.5.

Fusion of gun drill machine development and deep hole machining technology! Achieving ultra-small diameter deep hole machining in the field.

last updated

-

Possesses over 1,000 types (industry-leading) of gun drills.

We can also handle special jigs made in-house! We can prepare and select suitable machines, tools, and jigs.

last updated

-

No engineering changes required! High-precision deep hole machining on processed workpieces.

Absolute confidence in processing accuracy through processing technology! Capable of performing high-precision deep hole machining.

last updated

-

Multi-functional Gundrill Deep Hole and Internal Processing Service

Supports a variety of internal shapes such as tapered SR, stepped, and through-hole designs.

last updated

-

[Case Study] Molds (Injection Molding and Aluminum Extrusion) Industry

Introducing a case where cooling performance was improved, gas escape was enhanced, and post-processing was reduced!

last updated

-

[Processing Example] Industrial Machinery (Hydraulic and Cooling Mechanisms) Industry

Introducing examples of achieving stable flow, reduced assembly man-hours, and high reliability!

last updated

-

[Processing Examples] Precision Equipment / Food Machinery / Medical Device Industry

We will introduce examples of achieving improved device accuracy, reduced vibration, and easier assembly!

last updated

-

[Processing Example] Automotive Mold/Fixture Device Industry

We will introduce a case that achieved improvements in assembly accuracy, stable jig lifespan, and yield enhancement!

last updated

-

[Processing Example] Resin Mold Industry

Introducing a case study that achieved quality stability, reduced gas accumulation, and improved molding cycles!

last updated

-

[Case Studies] Precision Equipment/FA Equipment/Analytical Equipment Industry

Introducing examples of achieving improved device performance, reduced adjustment work, and enhanced yield!

last updated

-

Technical consultation service for deep hole machining of small diameters (less than φ3mm)

Technical consultation for small-diameter deep holes under 3mm is available from the design stage.

last updated

-

Case study of mass production processing of fine diameter deep holes for semiconductor devices.

Achieving stable mass production processing even under long-length conditions with a diameter of 1.5mm.

last updated