[Processing Example] Automotive Mold/Fixture Device Industry

We will introduce a case that achieved improvements in assembly accuracy, stable jig lifespan, and yield enhancement!

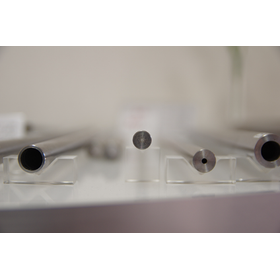

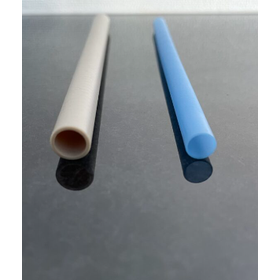

We would like to introduce a case study of deep hole machining on both sides of positioning shafts used in automotive molds and jigs. In this case, there were challenges such as the tendency for misalignment during dual-side machining and significant effects of thermal deformation. However, through our company's efforts, we were able to achieve improvements in assembly accuracy, stability of jig lifespan, and yield rate. Our company has many years of experience and advanced technology in the fields of deep hole machining and gun drilling. Utilizing our advanced gun drilling technology, which enables precise deep hole machining, we provide high-quality machining services tailored to our customers' requirements. 【Case Overview】 ■ Industry: Automotive molds/jig devices ■ Part Information: S45C, φ3×130mm dual-side machining, tolerance ±0.01 to 0.02mm ■ Challenges: Tendency for misalignment during dual-side machining / significant effects of thermal deformation ■ Provided Value: Established a stable machining process with eccentricity of 0.02 to 0.03mm and mass production capability ■ Technical Points: Multi-stage centering, optimization of dual-side machining sequence, warpage correction technology *For more details, please download the PDF or feel free to contact us.

basic information

【Other Case Overview】 ■Quality Control: Hole core measurement, front and back position accuracy verification, coaxiality confirmation ■Lot/Delivery: 8 pieces, small lot with short delivery time, flexible response ■Final Results: Improved assembly accuracy, stabilized tool life, improved yield *For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

Haitak boasts industry-leading contract gun drilling processing technology, catering to a wide range of industries including medical, aerospace, automotive, and semiconductors. Our in-house developed gun drilling machines are equipped with high rotational precision and built-in servo spindles, enabling deep hole processing exceeding L/D200. By manufacturing over 1,000 types of gun drills and special jigs in-house, we meet all customer needs. From small diameter to large-scale operations, we contribute to solving customer problems with precision and speed. Our machines, equipped with unique technology and international patents, excel in reliability and cost performance, making them the optimal choice for engineers. Haitak resolves all challenges in deep hole processing and provides complete satisfaction to our customers.