Case study of mass production processing of fine diameter deep holes for semiconductor devices.

Achieving stable mass production processing even under long-length conditions with a diameter of 1.5mm.

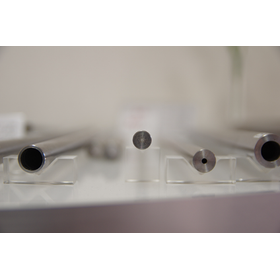

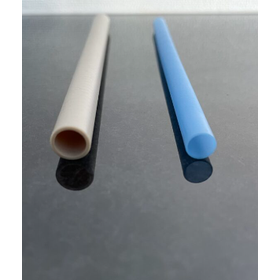

This case study involves mass production of parts for semiconductor manufacturing equipment, specifically focusing on deep hole machining with a diameter of φ1.5mm. Despite the long length condition of approximately 180mm, we have established stable machining conditions through gun drilling, maintaining a production rate of over 200 pieces per day. Due to the small diameter and high L/D ratio, issues such as vibration during machining and variations in inner diameter are challenges; however, we have stabilized inner diameter accuracy by optimizing setup methods and cutting conditions. No defects have occurred in the full inspection, ensuring both reproducibility and supply stability for mass-produced parts. 【Features】 ■ Mass production achievements for φ1.5mm fine diameter deep holes ■ Stable inner diameter accuracy even under long length conditions ■ Capable of continuous production exceeding 200 pieces per day ■ Quality control system through full inspection *For more details, please download the PDF or feel free to contact us.

basic information

- Target industry: Semiconductor manufacturing equipment - Processing diameter: φ1.5mm - Processing depth: Approximately 180mm - Processing method: Gundrill deep hole processing - Production quantity: More than 200 pieces per day - Measured inner diameter: 1.48 to 1.50mm - Quality results: 0 defective pieces (all good products)

Price range

Delivery Time

Applications/Examples of results

- Precision internal hole components for semiconductor manufacturing equipment - Mechanism components with narrow flow paths - Device assembly components intended for mass production - Components requiring stability in inner diameter precision - Continuous mass production projects under small diameter and long length conditions

Recommended products

Distributors

Haitak boasts industry-leading contract gun drilling processing technology, catering to a wide range of industries including medical, aerospace, automotive, and semiconductors. Our in-house developed gun drilling machines are equipped with high rotational precision and built-in servo spindles, enabling deep hole processing exceeding L/D200. By manufacturing over 1,000 types of gun drills and special jigs in-house, we meet all customer needs. From small diameter to large-scale operations, we contribute to solving customer problems with precision and speed. Our machines, equipped with unique technology and international patents, excel in reliability and cost performance, making them the optimal choice for engineers. Haitak resolves all challenges in deep hole processing and provides complete satisfaction to our customers.