[Processing Example] Resin Mold Industry

Introducing a case study that achieved quality stability, reduced gas accumulation, and improved molding cycles!

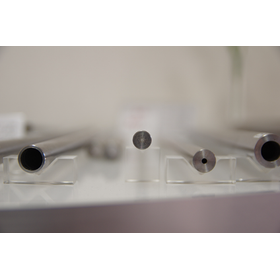

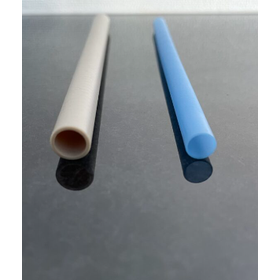

We would like to introduce a case study of manufacturing deep hole components made of heat-resistant steel used for gas venting in resin molds. In this case, there was a challenge of high machining load on heat-resistant steel and the need for high-precision processing of the tip shape. However, through our company's efforts, we achieved stable quality, reduced gas accumulation, and improved molding cycles. Our company has many years of experience and advanced technology in the fields of deep hole machining and gun drilling. Utilizing advanced gun drilling technology that enables precise deep hole machining, we provide high-quality processing services tailored to our customers' needs. 【Case Overview】 ■ Industry: Resin Molds ■ Part Information: SKD61, φ4.6×169.2mm, tip SR shape, deep hole machining ■ Challenge: High machining load on heat-resistant steel / Need for high-precision processing of the tip shape ■ Provided Value: Deep hole machining that suppresses thermal deformation / Achieving tip shape within ±0.01mm ■ Technical Points: Tools specifically for heat-resistant steel, high-pressure coolant, temperature rise suppression machining *For more details, please download the PDF or feel free to contact us.

basic information

【Other Case Summary】 ■Quality Control: Measurement of inner diameter, depth, and tip shape, straightness measurement ■Lot/Delivery: Can accommodate 1 piece and short delivery times ■Final Results: Quality stabilization, reduction of gas entrapment, improvement of molding cycle *For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

Haitak boasts industry-leading contract gun drilling processing technology, catering to a wide range of industries including medical, aerospace, automotive, and semiconductors. Our in-house developed gun drilling machines are equipped with high rotational precision and built-in servo spindles, enabling deep hole processing exceeding L/D200. By manufacturing over 1,000 types of gun drills and special jigs in-house, we meet all customer needs. From small diameter to large-scale operations, we contribute to solving customer problems with precision and speed. Our machines, equipped with unique technology and international patents, excel in reliability and cost performance, making them the optimal choice for engineers. Haitak resolves all challenges in deep hole processing and provides complete satisfaction to our customers.