Technical consultation service for deep hole machining of small diameters (less than φ3mm)

Technical consultation for small-diameter deep holes under 3mm is available from the design stage.

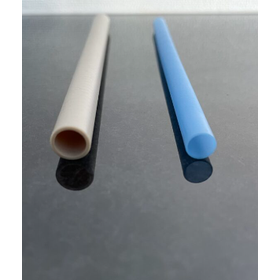

This service is a machining service that focuses on deep hole processing with a diameter of less than φ3mm, which is required for parts in the medical and precision fields, and provides technical consultation from the design consideration stage. As the diameter decreases and the length increases, it becomes more challenging to determine the feasibility of machining and set tolerances, so we organize machining methods and dimensional conditions from the stage when the drawings are not finalized. Utilizing setup and machining know-how that takes into account core misalignment and straightness, we offer proposals for machining methods that are practical and feasible. We also have experience with φ0.5mm class parts, but we consider them on a case-by-case basis depending on the conditions, emphasizing realistic feasibility judgments. We can also accommodate feasibility checks for prototypes and small lots. **Features** - Specializing in deep hole machining with a diameter of less than φ3mm - Technical consultation available even when drawings are not finalized - Proven machining experience in the medical and precision fields - Honest proposals that prioritize feasibility "This service is designed for consultations starting from the stage of wanting to confirm whether machining is possible." *For more details, please download the PDF or feel free to contact us.*

basic information

- Applicable diameter: Mainly for diameters less than φ3mm - Processing details: Small diameter deep hole machining (gun drilling) - Target shapes: Long and high L/D ratio workpieces - Material achievements: SUS, titanium alloys, aluminum, plastics, etc. - Applicable processes: Prototyping, small lot processing - Design support: Pre-consultation on dimensions, tolerances, and manufacturing methods

Price range

Delivery Time

Applications/Examples of results

- Deep hole machining of small-diameter medical device parts - Internal hole machining for precision equipment and FA equipment - Prototype verification of manufacturability for small-diameter, long-length parts - Small-diameter deep hole projects deemed difficult to process by other companies - Projects for feasibility study of machining at the conceptual stage

catalog(2)

Download All CatalogsRecommended products

Distributors

Haitak boasts industry-leading contract gun drilling processing technology, catering to a wide range of industries including medical, aerospace, automotive, and semiconductors. Our in-house developed gun drilling machines are equipped with high rotational precision and built-in servo spindles, enabling deep hole processing exceeding L/D200. By manufacturing over 1,000 types of gun drills and special jigs in-house, we meet all customer needs. From small diameter to large-scale operations, we contribute to solving customer problems with precision and speed. Our machines, equipped with unique technology and international patents, excel in reliability and cost performance, making them the optimal choice for engineers. Haitak resolves all challenges in deep hole processing and provides complete satisfaction to our customers.