SUS deep hole machining and medical applications

A detailed explanation of the basic properties of SUS materials, advanced deep hole machining techniques, and their countermeasures!

In the medical field, materials such as SUS (stainless steel) are essential to meet the high demands for safety and precision in medical devices, surgical instruments, and implants. While it excels in corrosion resistance and biocompatibility, its low thermal conductivity and work hardening characteristics require advanced technology and process management for deep hole machining. Here, we will provide a detailed explanation of the technical challenges and countermeasures in deep hole machining of SUS materials, as well as specific application examples in the medical field. *For more detailed information, please refer to the related links. Feel free to contact us for further inquiries.*

basic information

*You can view the detailed content of the article through the related link. For more information, please feel free to contact us.*

Price range

Delivery Time

Applications/Examples of results

*You can view the detailed content of the article through the related links. For more information, please feel free to contact us.*

catalog(1)

Download All CatalogsRecommended products

Distributors

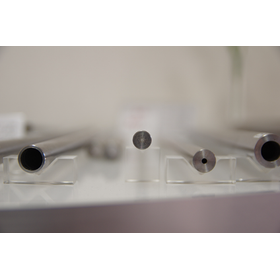

Haitak boasts industry-leading contract gun drilling processing technology, catering to a wide range of industries including medical, aerospace, automotive, and semiconductors. Our in-house developed gun drilling machines are equipped with high rotational precision and built-in servo spindles, enabling deep hole processing exceeding L/D200. By manufacturing over 1,000 types of gun drills and special jigs in-house, we meet all customer needs. From small diameter to large-scale operations, we contribute to solving customer problems with precision and speed. Our machines, equipped with unique technology and international patents, excel in reliability and cost performance, making them the optimal choice for engineers. Haitak resolves all challenges in deep hole processing and provides complete satisfaction to our customers.