Basic Knowledge of SUS Materials

Exploring the further possibilities of SUS materials, touching on our proud deep hole machining technology!

Isn't it true that there isn't a day in our daily lives when we don't see stainless steel products? For example, stainless steel is deeply embedded in our lives, from kitchen sinks and knives to building exteriors and even medical devices. You might be surprised to learn that the JIS standard name for stainless steel is referred to as "SUS materials." In this article, we will delve into the unknown charms and possibilities of SUS materials, exploring everything from basic knowledge to specialized processing techniques. *For more details, you can view the related links. Please feel free to contact us for more information.*

basic information

*You can view the detailed content of the article through the related links. For more information, please feel free to contact us.*

Price range

Delivery Time

Applications/Examples of results

*You can view the detailed content of the article through the related link. For more information, please feel free to contact us.*

catalog(1)

Download All CatalogsRecommended products

Distributors

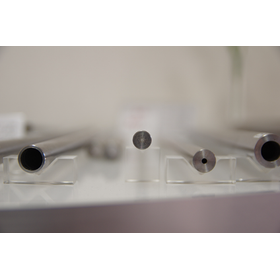

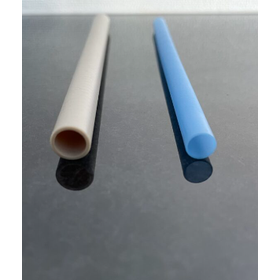

Haitak boasts industry-leading contract gun drilling processing technology, catering to a wide range of industries including medical, aerospace, automotive, and semiconductors. Our in-house developed gun drilling machines are equipped with high rotational precision and built-in servo spindles, enabling deep hole processing exceeding L/D200. By manufacturing over 1,000 types of gun drills and special jigs in-house, we meet all customer needs. From small diameter to large-scale operations, we contribute to solving customer problems with precision and speed. Our machines, equipped with unique technology and international patents, excel in reliability and cost performance, making them the optimal choice for engineers. Haitak resolves all challenges in deep hole processing and provides complete satisfaction to our customers.