Utilization of Outsourcing Network for Integrated Machining Services

Comprehensive support for machining, heat treatment, and procurement through deep hole processing and outsourcing collaboration.

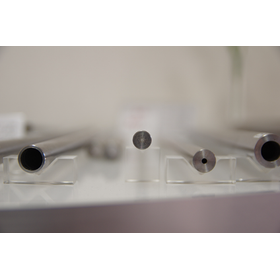

This service is a machining service that combines in-house equipment and an outsourcing network based on deep hole machining technology using gun drilling, allowing for comprehensive support from general cutting processes to subsequent operations. We perform high-precision machining of fine deep holes starting from φ0.5mm and long parts in-house, while collaborating with established partners for larger diameter machining, complex shapes, heat treatment, and polishing processes that exceed our capabilities. We manage the entire process and establish machining routes tailored to drawing requirements and usage conditions. We can also accommodate the procurement of long pipes, secondary processing, and BTA deep hole machining for diameters of 30mm or more. 【Features】 ■ Consistent support through in-house deep hole machining and outsourcing collaboration ■ Consolidated process management from cutting to heat treatment and polishing ■ Consultation available for long materials and large diameter machining ■ Flexible support from prototyping to mass production *For more details, please download the PDF or feel free to contact us.

basic information

- In-house deep hole processing: Gundrilling for diameters from φ0.5mm - Supported processing: Turning, machining, wire cutting, etc. - Subsequent processes: Hardening, polishing/grinding, surface treatment - Long materials: Procurement and secondary processing of pipe materials - Large diameter deep holes: Approximately φ30 to φ100 using BTA method (as a guideline) - Difficult-to-machine materials: Proven track record in processing Inconel, titanium, etc. - Process management: Unified management of quality and delivery by our company

Price range

Delivery Time

Applications/Examples of results

- Production of parts combining deep hole machining and outer diameter cutting - Comprehensive support from procurement to processing of long pipes - Parts processing including finishing polishing after hardening - Multi-process support for prototype parts for research and development - Large diameter deep hole parts (BTA machining) with a diameter of 30mm or more

catalog(1)

Download All CatalogsRecommended products

Distributors

Haitak boasts industry-leading contract gun drilling processing technology, catering to a wide range of industries including medical, aerospace, automotive, and semiconductors. Our in-house developed gun drilling machines are equipped with high rotational precision and built-in servo spindles, enabling deep hole processing exceeding L/D200. By manufacturing over 1,000 types of gun drills and special jigs in-house, we meet all customer needs. From small diameter to large-scale operations, we contribute to solving customer problems with precision and speed. Our machines, equipped with unique technology and international patents, excel in reliability and cost performance, making them the optimal choice for engineers. Haitak resolves all challenges in deep hole processing and provides complete satisfaction to our customers.