Product Categories

-

Cavitation in pumps and how to avoid it

-

Exhaust gas measurement

-

Silencer for micro pumps

-

Noble gas recovery

-

Helium recovery and filling

-

Biogas

-

EV charging station cooling liquid pump

-

Foot care techniques and podiatric treatment.

-

Laser dental treatment

-

High-temperature gas sampling pump

-

Pump for commercial dishwashers

-

Water-based ink / water-soluble ink

-

Pump lifespan test

-

Diaphragm pump and tube pump

-

Five signs before the pump fails

-

Leak test leak rate

-

Pump accessories

-

Reduction of CO2 emissions and reuse

-

Extracorporeal Shock Wave Therapy: The Key to Effective Shock Wave Therapy

-

LNG propulsion for ships

-

Cryostat system

-

Diaphragm vacuum pump for exhaust of turbo molecular pump

-

Micro pump for coffee machines

-

The optimal vacuum pump for rotary evaporators.

-

Vacuum pump for automation technology

-

Process pump pump head water cooling

-

Disinfection technology using hydrogen peroxide

-

CO2 carbon dioxide pump

-

Comparison of diaphragm pumps and gear pumps

-

An ideal solution for efficient needle cleaning.

-

Renewable energy green hydrogen gas pump in the electrolysis process.

-

Noble gas

-

Megnajet / Xaar pump for inkjet systems

-

Rotary evaporator for organic solvent recovery

-

Hydrogen pump

-

Gas pump for SF6 sulfur hexafluoride

-

Vacuum dryer

-

Attraction filtration, vacuum filtration

-

Full Teflon Pump

-

Self-driving valve built-in vacuum pump

-

Vacuum desiccator

-

Labport Series Desktop Type N86 / N811

-

Metering pump

-

Diaphragm Liquid Delivery Pump LIQUIPORT Liquiport Series

-

Labport Series Desktop Type N816/N838/N938

-

NEW LOBOPORT Chemical-resistant Diaphragm Vacuum Pump

-

OEM Comprehensive Catalog

-

Gas pump

-

Liquid pump

-

Micro gas pump

-

Sampling pump for gas

-

Process pump

-

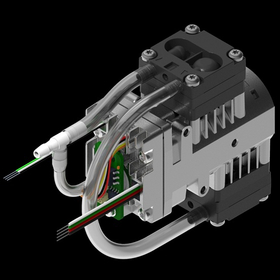

DC-BI Series: Integrated Pump and Motor, Next-Generation Pump Series

-

Pulsation Reduction Liquid Pump FP Series

-

Dispensing and titration liquid pump

-

Drainage and waste liquid pump

-

Small vacuum pump for degassing

-

Explosion-proof gas pump

-

Heat-resistant gas pump

-

Vacuum pump for steam sterilization autoclave

-

Pulsation Reduction Damper FPD

-

Pressure regulating valve FDV

-

Swing piston oscillating piston type gas pump

-

Inkjet printer ink transfer liquid pump

-

NSF certified component liquid pump

-

Vacuum drying vacuum pump for reduced pressure drying

-

Compressor gas pump specialized for pressurization.

-

Vacuum pump specialized in gas pumping with reduced pressure performance.

-

High discharge liquid pump - A liquid pump specialized for discharge performance.

-

Liquid pump specialized in suction performance.

-

Auxiliary pump for turbo molecular pump, roughing pump

-

Fuel cell

-

Laboratory gas pump

-

Laboratory liquid pump

Featured products

Products/Services(210items)

news list

-

Diaphragm Pump vs. Swing Piston Compressor: Choosing the Right Gas Pump Solution

Diaphragm pumps and swing piston compressors are both strong options for gas applications. What are the advantages and disadvantages of these technologies? When selecting a pump for gas applications, various technologies can be chosen. Among these technologies are diaphragm pumps and swing piston compressors. Both types of pumps have proven effective in various gas applications. Diaphragm pumps and swing piston compressors each have strengths that make them particularly effective for specific applications.

-

Our efforts towards a sustainable future.

Commitment to Sustainability As a family-owned business, we are committed to creating a better world for future generations. This commitment serves as a guideline for our efforts to improve the sustainability of our business activities. The principles and code of conduct of KNF, passed down over many years, ensure that all employees respect human rights and protect the environment. The decentralized organization of the KNF Group supports each location in leading sustainability initiatives suited to their communities. We also promote global initiatives aligned with our comprehensive sustainability strategy, fostering sustainable growth throughout the organization.

-

The diaphragm vacuum pump for vacuum grippers guarantees the absolute precision of the robotic arm.

Automated systems use robotic arms for pick-and-place tasks. These robots rely on high-performance vacuum pumps in vacuum grippers to achieve high-speed and precise movements. Manufacturers, intralogistics, and warehouse operators around the world are facing a labor shortage. This has increased the need for automated systems using industrial robots. These robotic arms are used for repetitive and monotonous pick-and-place tasks in dynamic environments, requiring precise movements. The vacuum pumps mounted on the robots' vacuum grippers provide the necessary suction accuracy.

-

Proper material selection in liquid pump lines

The pump tubing in a delivery system can have a significant impact on the performance of the pump. When connecting a liquid diaphragm pump to a system, engineers face numerous material choices for both the suction and discharge pump lines. Selecting the appropriate material is often more complex than it may initially seem. Therefore, it is extremely important to understand the most significant positive and negative impacts that the pump piping materials can have, as well as to know how to avoid or leverage those impacts.

-

Announcement of management change - Alexander Heisler appointed as CEO.

Martin Becker, who has been with KNF for over 40 years and has achieved success as CEO for 26 of those years, has passed the CEO position to Alexander Heitzler, who has been with KNF since 2009 and has served as COO since 2021. Martin Becker will now focus on his role as Chairman of the Board. This decision marks his complete withdrawal from operational duties and brings an end to a carefully planned transition period. This change in management reflects KNF's long-term stability and its identity as a family-owned business.

Aboutケーエヌエフ・ジャパン

KNF JAPAN

The success of our customers is what we aim for as a company. That will not change now or in the future.

KNF was founded by Kurt Neuberger in 1946 in Freiburg, Germany (Freiburg im Breisgau). Since then, we have been a family-owned independent company providing our customers with security and stability. Over the years, we have achieved steady growth and expanded our business globally while accumulating experience. Currently, with 17 subsidiaries worldwide, we continue to deepen our expertise in various industries and advance the expansion of product applications. As a company specializing in the development, design, manufacturing, and sales of diaphragm pumps and gas and liquid handling systems, we have established our position globally as a provider of customer-oriented solutions to address challenges. Innovation means having an open attitude towards new approaches and various methods, and appropriately judging and identifying what will be needed for the future. By bringing together expertise from various engineering fields, including mechanical engineering, materials, fluid engineering, electronics, and software, we strive to find optimal and smart solutions for all applications, not only for our customers' current needs but also for their future requirements.