news list

latest news

Liquid suction: direct liquid transfer and liquid overhead vacuum transfer

Liquids can be suctioned using either direct liquid transfer or vacuum over liquid methods. It is important to understand these differences when selecting the appropriate technique and pump solution. …

61~85 item / All 85 items

-

Diaphragm pump: advantages and disadvantages

Diaphragm pumps have advantages and disadvantages that need to be considered when selecting the appropriate pump technology for an application. By examining these advantages and disadvantages in detail, we can evaluate the strengths and weaknesses of this type of pump and make an informed decision when choosing the right pump.

-

The mechanism of a diaphragm pump.

- What is a diaphragm pump? - What is the function of the diaphragm in a diaphragm pump? - Operating principle of a diaphragm pump - Applications of diaphragm pumps - Knowledge and support for diaphragm pumps

-

Radiation monitoring pumps enhance the safety of nuclear power plants.

- Air Monitoring - The Cornerstone of Nuclear Safety - Pump for Radiation Monitoring: Ideal Diaphragm Technology - Collaboration with Partners and Suppliers - Long-term Operation Required for Radiation Monitoring Pumps - Outstanding Pump Expertise in the Nuclear Field

-

Changes to the system and operation for a quiet diaphragm pump.

When the operation of a quiet diaphragm pump is important, there are many system changes to consider. - The key to a quiet diaphragm pump is the installation location of the pump. - The mounting surface is important. - Tubing can be a source of noise... - ...or assist the quiet diaphragm pump. - Reduce noise with continuous pumping. - Be aware of potential trade-offs. - Testing is crucial to achieve a quiet diaphragm pump.

-

NEW LOBOPORT Chemical Resistant Diaphragm Vacuum Pump

LABOPORT N96.18 LABOPORT N820G LABOPORT N840G

-

Silencer for micro pumps

Silencer for KNF Micro Pump - Silencer for bamboo joint - Silencer with tube - Noise-canceling tube

-

The diaphragm pump protects the insulation gas of the electrical system.

To safely handle current in applications from medium voltage to high voltage, insulating gases like SF6 are essential for the protection of electrical systems. Since SF6 has a significant impact on the environment, a strict sealing system is required. - SF6 gas ensures the safety of circuit breakers and switchgear - Diaphragm pumps maintain the integrity of high voltage systems - Extraction of SF6, discharge of air or nitrogen, replenishment of SF6 - Efficiency improvements through customization

-

Pump customization

What are the advantages of custom pumps? - Correctly setting the operating point - Achieving high chemical compatibility with custom pumps - No need for adapters with custom pumps - Reduction in system costs - The lifespan of custom pumps leads to further cost savings - Protection of confidential information - The path to a perfect custom pump: collaboration

-

How to minimize pump noise through customization.

Various customizations are possible to reduce pump noise. In diaphragm pumps, several factors contribute to noise. These include the motor, bearings, diaphragm, valves, suction inlet, and discharge outlet. - Reducing motor speed to lessen diaphragm pump noise - Decreasing bearing play to reduce pump noise - Optimizing the diaphragm - Customizing valve materials to reduce diaphragm pump noise - An obvious choice to reduce pump noise: silencers - Reducing pump noise with shock mounts - Is diaphragm pump noise sometimes beneficial?

-

Pump for DOD drop-on-demand printer

Diaphragm Pump for Digital Inkjet Gentle Flow diaphragm pump for drop-on-demand digital inkjet contributes to reducing complexity. With advancements in technology, diaphragm pumps are becoming an excellent pump option for drop-on-demand printing systems.

-

Pumps for CIJ that enable next-generation printing systems.

Latest pump for continuous inkjet systems Pump for CIJ that enables next-generation printing systems As diaphragm pump technology evolves, diaphragm pumps become an excellent alternative to gear pumps in CIJ systems.

-

Overview of Gas Pump Leak Test Method

KNF offers a variety of leak testing methods tailored to customer needs, ranging from simple bubble tests to advanced helium leak tests.

-

LABOPORT Pump & System Maintenance Procedures

Target Pumps & Systems: N 820 G / N 840 G / SR 820 G / SR 840 G / SH 820 G / SH 840 G / SC 820 G / SC 840 G

-

N84 Series Simple Maintenance Procedure

This is the replacement procedure for the diaphragm and valve of the N84 series.

-

Fuel cell system hydrogen recirculation vacuum pump

We propose the KNF vacuum pump, which is optimal for hydrogen recirculation in fuel cell systems, combining technical challenges such as pump airtightness and energy efficiency. With KNF's unique digital customization, it is possible to achieve the ideal design for your system.

-

KNF announces next-generation motor technology.

The new brushless motor options developed by KNF enable next-generation pump technology with unprecedented advantages. Pumps are all about drive. This insight led KNF to take a significant step forward by fundamentally rethinking the entire drive unit, including the motor, pump housing, and mechanical drive components. The new drive unit is called KNF DC-BI and is equipped with an advanced brushless DC motor developed in-house.

-

N922 Series Simple Maintenance Procedure

This is the procedure for replacing the diaphragm and valve of the N922 series.

-

New Design Concept - Brushless DC Motor DC-BI

The DC-BI is the first brushless DC motor developed in-house by KNF in its history. This next-generation brushless motor further enhances the advantages of KNF diaphragm pumps, such as performance, robustness, durability, and digital customization features. The new diaphragm pump is very compact due to a new motor mount concept that integrates the motor into the pump housing. The motor is positioned near the ball bearings, and its dimensions have also been optimized. This reduces the load on the pressure and vacuum pump, extending the pump's lifespan. Additionally, we have developed electronics and software equipped with new features that enable full control of the motor. This allows for the individual programming of motor characteristics and control. The pump characteristic curve can be customized and precisely defined to meet exact needs. Extensive parameterization is a key feature of all KNF motors in the "Digital Customization" series.

-

Explosion-proof certification in Japan - Explosion-proof gas pump

The explosion-proof gas pumps of the N87 series and N922 series, which have received positive feedback for sampling combustible gases and gas transfer, have passed the explosion-proof structure electrical equipment type certification in Japan. Against the backdrop of initiatives such as the "2050 Carbon Neutral Declaration," applications handling combustible gases, including methanation and hydrogen gas utilization, are increasing daily, and practical demonstration experiments are actively being conducted. KNF offers a wide range of explosion-proof gas pumps certified with IECEX / ATEX that are suitable for combustible gases, including hydrogen gas, and many customers are already using them. In response to the demand for explosion-proof certified products in Japan, we have obtained explosion-proof certification for two models of compact gas pumps.

-

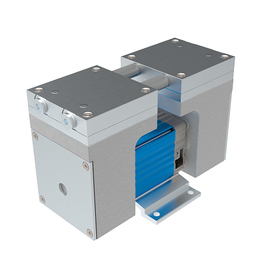

KNF High-Output Liquid Pump High-Pressure Liquid Pump

The KNF high-output liquid pump enables stable liquid delivery against high back pressure. It is available in a lineup categorized by flow rate types. Standard specification high-output liquid pump: Maximum allowable discharge pressure 0.6 MPa Special specification high-output liquid pump: Maximum allowable discharge pressure 1.6 MPa (NF2.35 series) - Abundant wetted materials Available from inexpensive EPDM to highly corrosion-resistant Perfluoro materials. Capable of high-pressure transfer of solvent-based and cleaning liquids. - Compression fittings The pump joints come standard with highly compatible connectors. - Brushless DC motor Flow control is possible through analog control or PWM control. - No restrictions on installation direction There are no restrictions on the installation of the pump.

-

How to read the KNF flow curve

This explains a simple way to read the flow curves (performance curves) found in pump data sheets, etc. The video explains the flow curve for gas pumps, but the basic reading method is the same for liquid pumps, swing piston compressors, and others. If you have any questions regarding the flow curves of individual pumps, please feel free to contact our experts.

-

Introduction to Pumps for Medical Applications

In medical applications where system reliability is essential, the high-quality and reliable KNF diaphragm pumps have a long history of adoption in medical systems and analytical systems produced worldwide. *Examples of Adoption - Biochemical automatic analyzers Blood testing devices (blood analysis, blood cell counters, etc.) Urinalysis devices, fecal occult blood analysis devices, etc. - Immunoassay devices, bioanalytical devices, molecular biology - Endoscope cleaning devices - Artificial dialysis - Various sterilization, disinfection, cooling, etc. *Main Product Features - Design specialized for drainage and waste liquids - Longevity - Corrosion resistance - Maintainability - Compact, lightweight, and quiet - Installability

-

Introduction to KNF Process Pumps

As efforts towards carbon neutrality by 2050 and the realization of a hydrogen society gain attention, KNF is seeing an increase in inquiries regarding various process gases. * Gases with increasing inquiries: - Carbon dioxide - Hydrogen - Methane - Oxygen, etc. At KNF, we have prepared a simple presentation material regarding pumps for process gases. It explains the features of our process pumps and various data sheets, so we would appreciate it if you could refer to it.

-

Recent technical challenges in ink supply systems.

In February 2021, we translated into Japanese the presentation materials used in the webinar "Market Trends in Inkjet and KNF's Initiatives" that KNF presented at DRUPA (International Printing and Media Industry Exhibition), which was held as a virtual exhibition. The main themes are as follows: - Pulsation-reducing liquid pump - Digitally customizable DC motor - Vacuum pump for degassing - Meniscus countermeasures for printer heads, etc.

-

KNF Modular System

KNF's OEM pumps (equipment integration type) can be customized to meet various challenges of our customers. Here, we would like to introduce the KNF modular system.