DLC Coating, DLC System “Low temperature deposition” “Hard to peel off”

The plasma ion implantation method enables diamond-hard, low-friction, high-cohesion coatings on various shapes and sizes of metals, resins, and rubber materials.

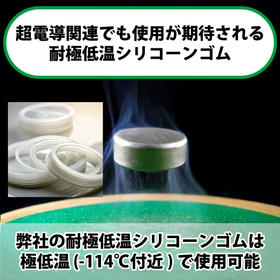

DLC (diamond-like carbon) coating deposits a low-friction DLC film using plasma ion implantation coating method. 【Features】 ■Capable of handling work with complicated shapes ・By using the work itself as a source of plasma, plasma is formed along the shape of the work and allows gas to flow around and deposit a film on complicated shapes and interiors. ■Excellent lubricity ・Excellent lubricity due to the formation of low coefficient of friction film ■Can deposit on resin and rubber as well as metal and aluminum. ・Low-temperature deposition is possible. ■Can deposit with the flexibility to follow the shape of the base material (even resin is resistant to film peeling). *Please contact us if you have any problems with life reduction due to friction of parts. *We can provide technical explanations and trial production. *We also sell DLC deposition system. * For more details, please contact us or download our catalog for more information.

basic information

Deposits low-friction DLC films using plasma ion implantation deposition method. By using the workpiece itself as a source of plasma, plasma is formed along the shape of the workpiece, allowing the gas to penetrate the complex shapes and interior of the workpiece to form the film. Ion implantation allows deposition ions to penetrate the workpiece surface and achieve high adhesion to the deposited film. ・Low coefficient of friction film formation provides excellent lubricity. ・Can be applied to workpieces with complex shapes. ・Low temperature deposition is possible on resin, rubber, metal, and aluminum. ・Film can be deposited with flexibility to follow the shape of the base material, and it does not peel off easily even on resins. *For more details, please contact us or download and view the catalog.

Price information

Please contact us.

Delivery Time

Applications/Examples of results

【Applications】 ・Semiconductor manufacturing parts: Improvement of wear resistance, prevention of metal contamination, etc. ・Various packing: Improvement of sliding property, durability, and chemical resistance ・Track record in a wide range of fields including molds, equipment parts, and jigs *For more details, please contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

Founded in 1930 as a specialized trading company for imports and exports, we celebrated our 90th anniversary in 2020 and are fully committed to the further development of the M.WATANABE Group. Since the mid-1960s, we have started manufacturing and selling our own products such as quartz processed products, silicone rubber molded products, and cleaning equipment, under the policy of selling silicon (Si) related products to the semiconductor industry. As a manufacturing trading company, we have grown alongside the IT society by providing high-quality products and services. Moving forward, we aim to create a company where employees of the group companies, centered around M.WATANABE & CO.,LTD., work vibrantly every day, and the entire workplace becomes a learning organization. We are determined to continue striving in all our business endeavors with a strong will to respond to the true needs of society. We sincerely ask for your continued support and patronage.