Surface Modification Treatment Processing and Jig Cleaning (TOMCO)

Maintenance of jigs and parts is from quality maintenance and improvement. Our thermal spraying and cleaning technology reproduces high quality without damaging the base material.

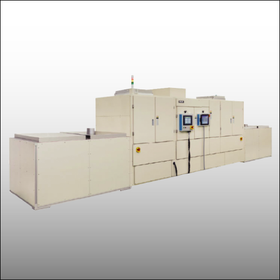

In addition to the cleaning and reconditioning technologies, that Tomco boasts a long track record of, we have achieved complete in-house production of thermal spraying, a surface modification technology in which powder is melted and coated on the surface of materials. 【Features】 ■ Achieving high densification, high insulation properties, wear resistance, and corrosion resistance ・We provide coating technologies that achieve high densification, high insulation properties, wear resistance, and corrosion resistance under thermal spraying conditions optimized for the materials and shapes of jigs and parts. ■High-quality reproduction of parts and jigs ・We provide high-quality reproduction of parts and jigs incorporated in vacuum chambers through our integrated production and management systems, from ultrasonic ultrapure water cleaning in our clean room to decompression drying and vacuum packing. ■We also support ultrapure water cleaning and vacuum packing. ・We support customers in the precision machinery field and other fields to improve their productivity through precision cleaning that removes invisible dirt and residual materials. ■Supporting productivity improvement ・We provide highly reproducible technical capabilities to always deliver products that are equivalent to evaluated products. *For more details, please contact us or download and view our catalog.

basic information

In addition to the cleaning and reconditioning technologies that Tomco boasts a long track record of, we have achieved complete in-house production of thermal spraying, a surface modification technology in which powder is melted and coated on the surface of materials. 【Features of Surface Modification Processing】 ・Surface modification can be optimized to the base material by applying a protective film or other surface treatment. ・Surface modification process reduces particles in parts of thin film manufacturing system. 【Features of Jig Cleaning】 ・In addition to chemical and physical cleaning that minimizes damage to base materials, we also offer ultra-pure water cleaning and vacuum packing in clean rooms. ・We support customers in the precision machinery field and other fields to improve their productivity through precision cleaning that removes invisible dirt and residual materials. ・We provide highly reproducible technical capabilities to always deliver products that are equivalent to evaluated products. *For more details, please contact us or download our catalog for further information.

Price range

Delivery Time

Applications/Examples of results

【Applications】 ・PVD system jigs and parts ・CVD system jigs and parts ・Etching system jigs and parts, etc. *For more details, please contact us or download and view the catalog.

catalog(1)

Download All CatalogsRecommended products

Distributors

Founded in 1930 as a specialized trading company for imports and exports, we celebrated our 90th anniversary in 2020 and are fully committed to the further development of the M.WATANABE Group. Since the mid-1960s, we have started manufacturing and selling our own products such as quartz processed products, silicone rubber molded products, and cleaning equipment, under the policy of selling silicon (Si) related products to the semiconductor industry. As a manufacturing trading company, we have grown alongside the IT society by providing high-quality products and services. Moving forward, we aim to create a company where employees of the group companies, centered around M.WATANABE & CO.,LTD., work vibrantly every day, and the entire workplace becomes a learning organization. We are determined to continue striving in all our business endeavors with a strong will to respond to the true needs of society. We sincerely ask for your continued support and patronage.