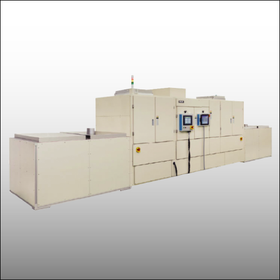

High-productivity Continuous Atmospheric Pressure CVD (APCVD) System (AMAX1200)

Mass production / NSG(SiO2)/PSG/BPSG deposition High-productivity / Continuous atmospheric pressure CVD (APCVD) system (for 12-inch wafers)

The AMAX series is a continuous atmospheric pressure CVD system (APCVD system) for silicon oxide (SiO2) deposition, such as an interlayer insulator deposition, passivation deposition (protective deposition), and back seal (for epitaxial wafers). 【Features】 ・High productivity of up to 56 wafers/h (wafer size: up to 12 inches) ・No vacuum or plasma is required (thermal CVD) ・SiC trays are used to prevent heavy metal contamination. ・Simple maintenance. ・Low CoO (low running cost) 【Applications】 ・Back seal for epitaxial wafers (NSG) ・Passivation deposition (protective deposition, insulating deposition) (NSG) *For more details, please contact us or download the catalog to view.

basic information

High throughput (high productivity) is achieved by continuously conveying a tray with wafers on it and passing it under the dispersion head (gas nozzle) while heating it from the bottom. The use of SiC for the tray material minimizes heavy metal contamination to ensure stable process performance over the long term.The AMAX1200 is easy to maintain, with an automatic replacement function that facilitates tray replacement. The AMAX1200 can handle wafers up to 12 inches and can deposit up to 56 wafers per hour. ●System size (mm): 2165mm(W) x 4788mm(D) x 2250mm(H) ●Gas type: SiH4/O2 (SiH4/PH3/B2H6/O2/N2) ●Deposition temperature: 350-430 degrees C. *For more details, please contact us or download the catalog to view.

Price range

Delivery Time

Model number/Brand name

AMAX1200

Applications/Examples of results

【Applications】 ・Back seal for epitaxial wafers (NSG) ・Passivation deposition (protective deposition, insulating deposition) (NSG) 【Delivery Record】 ・Domestic and overseas wafer manufacturers ・Semiconductor device manufacturers ・AMAX series total: More than 180 units

catalog(1)

Download All CatalogsRecommended products

Distributors

Founded in 1930 as a specialized trading company for imports and exports, we celebrated our 90th anniversary in 2020 and are fully committed to the further development of the M.WATANABE Group. Since the mid-1960s, we have started manufacturing and selling our own products such as quartz processed products, silicone rubber molded products, and cleaning equipment, under the policy of selling silicon (Si) related products to the semiconductor industry. As a manufacturing trading company, we have grown alongside the IT society by providing high-quality products and services. Moving forward, we aim to create a company where employees of the group companies, centered around M.WATANABE & CO.,LTD., work vibrantly every day, and the entire workplace becomes a learning organization. We are determined to continue striving in all our business endeavors with a strong will to respond to the true needs of society. We sincerely ask for your continued support and patronage.