Machinable Ceramics "Hotober" for Semiconductor Manufacturing

Achieving both workability and thermal insulation! High-precision ceramic insulation materials.

In semiconductor manufacturing equipment, thermal insulation of components in high-temperature and high-heat environments is a challenge. Conventional insulation materials often lack heat resistance and processing precision, which can affect the performance and reliability of the equipment. Therefore, Narasaki Industries Co., Ltd. proposes "Hotobell," a machinable ceramic that combines high-precision processing with excellent thermal insulation performance. 【Application Scenarios】 - Insulation materials for semiconductor manufacturing equipment - Insulating components in high-temperature environments - Vacuum equipment parts - Heat treatment jigs - Situations requiring high-precision insulation materials 【Benefits of Implementation】 Hotobell contributes to the improvement of performance and reliability of semiconductor manufacturing equipment by achieving high-precision processing and excellent thermal insulation performance that were not possible with conventional insulation materials. - Ensures stable operation of components in high-temperature environments - Reduces degradation of equipment due to heat - Enables precise temperature control - Shortens delivery times by reducing processing time

basic information

【Features】 - Excellent machinability, resulting in fast processing speed and delivery advantages - Low cost - Low thermal conductivity, providing insulation properties - Excellent electrical insulation properties - Superior thermal insulation Our Strengths Narasaki Sangyo Co., Ltd. leverages years of experience and achievements as a specialized manufacturer of ceramics processing to provide high-quality products tailored to customer needs. - Extensive experience and track record in ceramics processing - High-precision processing technology - Quick delivery response - Capability to handle a variety of materials and surface treatments - Support from prototype development for single units to mass production - Actively engaged in overseas materials - Supporting customers in solving their challenges

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

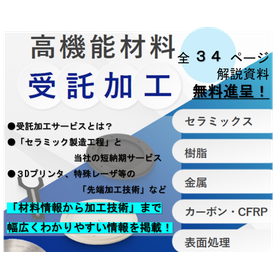

Narasaki Sangyo Co., Ltd. "Functional Materials Division" specializes in high-performance material contract processing. The materials we handle fall into "five categories": 1. Ceramics/Glass 2. Metals 3. Engineering Plastics 4. Carbon 5. Surface Treatment We offer a wide range of services, and if you provide us with a single production drawing, we can deliver various materials and surface treatments as a one-stop solution. We cater to everything from general-purpose to specialty materials, including high-precision, fine, electrical discharge, laser processing, as well as surface treatments such as coating, precision cleaning, and blasting. Our particular strength lies in high-precision and short-lead-time processing of ceramics. By machining from pre-fired materials, we achieve short lead times for ceramics that traditionally take several months. We handle a wide range of ceramics, including machinable ceramics like Hotovel, as well as fine ceramics such as alumina and zirconia, and non-oxide ceramics like silicon carbide, silicon nitride, and aluminum nitride. We are also actively engaged in proposing cost reductions for overseas ceramics and other international materials. We can accommodate various contract processing projects, from prototype development starting with a quantity of one to mass production.