Wind power generation protection sheet

The sheet method enables easy construction and high durability for the reinforcement and repair of wind turbine blades!

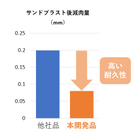

Wind turbines are exposed to the natural environment outdoors, and particularly the tips of the blades can reach speeds exceeding 150 km/h, gradually suffering damage from rain, wind, dust, and ultraviolet rays. Therefore, it is necessary to regularly repair the leading edge of the wind turbine with paint or other materials. In traditional methods using paint, there are concerns such as: - Multiple rounds of repairs are required - Construction conditions are limited by weather - Dependent on the skill of the workers By switching to a sheet method using protection sheets for wind power generation, it is expected that these concerns can be alleviated. Furthermore, the proposed protection sheet utilizes gel processing know-how, resulting in a highly durable protection sheet, which is expected to have superior wear resistance compared to other products.

basic information

Color: White Thickness: 0.6mm (can be adjusted according to your preference) Material: Polyurethane Shore Hardness: C55

Price range

P6

Delivery Time

OTHER

Applications/Examples of results

By attaching this sheet to the leading edge of the wind turbine blades, it reduces damage from rain, wind, sand, dust, and ultraviolet rays.

Detailed information

catalog(1)

Download All CatalogsRecommended products

Distributors

We respond flexibly and promptly to customer needs. In the "trading company" functional area, we are fully committed to providing truly attractive products and services that meet customer needs by collaborating with leading specialized manufacturers and utilizing advanced mechatronics technology to add value, thereby adapting to a highly information-oriented society. In the "mechanical parking equipment" business, we manufacture and install high-quality, environmentally friendly, and safety-conscious products to meet various customer needs. Based on our accumulated wealth of experience and technology, we provide 24-hour maintenance services through a nationwide service network, earning strong trust from our customers. The "freeze-drying equipment" business consistently develops next-generation "freeze dryers," including the sealed tube-type freeze dryer, which received the Minister of Economy, Trade and Industry Award from the Japan Industrial Machinery Manufacturers Association. We deliver and maintain both small-scale research and large-scale production equipment, and we also support the development of pharmaceuticals and food, establishing ourselves as an industry leader and receiving high praise. ◆ Locations Sapporo, Hitachi, Nagoya, Osaka, Fukuoka, Yamaguchi ◆ Overseas Subsidiary Thailand - Business activities: Sales of resin molded products, metal processed products, sheet metal, packaging materials, and electronic components.