news list

latest news

Regarding the internet and telephone line issues at the Yatsushiro Factory.

Due to a road collapse accident that occurred around 10 AM on January 28 (Tuesday) in the neighboring area, our Yashio factory (including the sales department) is experiencing disruptions to both inte…

241~270 item / All 502 items

-

[Custom Case] We have published a delivery case for a pharmaceutical manufacturer.

This is a stainless steel hopper equipped with a custom-made observation window that we supplied to a pharmaceutical manufacturer. We have installed a long, integrated observation window on the vertically elongated hopper to maximize the visible area. Additionally, we have added brackets on the side of the container for secure attachment to equipment or stands. For more details, please visit our website. https://www.nitto-kinzoku.jp/archives/48136/

-

[Custom Case] We have published a delivery case for a chemical manufacturer.

This is a sight glass with a handle and cover that we supplied to a chemical manufacturer. To make it easy to attach and detach, we installed a handle on the window. By using a cover, we can prevent damage to the window and the accumulation of dust. This time, it was manufactured to match the size and specifications requested by the customer. For more details, please visit our company website. https://www.nitto-kinzoku.jp/archives/47441/

-

[New Product] Container with card holder for differentiating usage and visualizing contents.

Stainless steel container with a holder for a clear case It allows for identification of contents and management of usage processes. Features ○ Cards can be inserted and removed from the top of the holder. ○ Ideal for identifying contents, managing processes, and handling documents such as manufacturing instructions. ○ Changes to the position and specifications of the holder, as well as installation on custom-made containers, are also possible. For more details, please visit our website. https://www.nitto-kinzoku.jp/archives/47145/

-

[New Product] Dust control measures during powder feeding! Hopper tank with dust collection hood.

Nitto Metal Industry's new product, "Hopper with Dust Collection Hood Legs [HTD-L]," is a stainless steel container that can be combined with dust collectors and air transporters to collect dust that rises during the loading of powdered raw materials. The large hood, designed to match the hopper size, efficiently collects dust, reducing cleaning time after powder loading and improving the hygiene of the workspace. As an option, it is also possible to install a blow disk, knocker, or vibrator to address powder clogging (bridging or rat holes). We also accept custom manufacturing according to your needs and applications. For product details, please visit our website. https://www.nitto-kinzoku.jp/archives/48427/

-

[New Product] Shutter valve with connections on both sides for Heller.

A new double-handle type shutter valve specifically designed for filling and feeding bulk materials has arrived! With a handle connection, it can be easily installed between containers and piping. This user-friendly valve features a simple structure that allows for disassembly and assembly without tools. Features: - It is effective in filling processes for powders and granules, as well as in the feeding of raw materials. - Both sides have handle connections, making attachment and detachment easy. - It slides smoothly thanks to the PTFE packing. - It includes a locking function to prevent accidental opening and closing of the valve. - Its simple structure allows for disassembly and assembly without the need for tools.

-

We will be exhibiting for the first time at the 4th Drink Japan!

Nitto Metal Industry will make its first exhibition at the 4th Drink Japan exhibition to be held in November. We will showcase products suitable for the manufacturing of beverages and the handling of liquid raw materials and liquid products. If you have any concerns regarding the handling of liquid raw materials, please feel free to consult us at any time. --Overview-------------------------------------------------- Date: November 27 (Wednesday) to 29 (Friday), 2019 Time: 10:00 AM to 6:00 PM (until 5:00 PM on the last day) Venue: Makuhari Messe, Booth Location: Hall 4, D5-30 Exhibited Products New Product: Stainless container for craft beer production (tentative) Others: Heater units, mixing vessel with a mirror plate type container (tank bottom valve) --------------------------------------------------------

-

[New Product] PFA piping with excellent corrosion resistance, cleanability, and high sanitary properties.

"I want to handle highly corrosive chemicals." "I want piping that requires little effort for cleaning." For you, we recommend our new product, PFA Sanitary Piping (Cynergy(R) Fittings and Valves). Features: - The wetted surface is made of PFA, so there is no worry about discoloration or holes even when handling corrosive media. - It has high non-stick properties, making it difficult for fluids to adhere, which results in excellent cleanability. - The wetted surface is made from FDA-approved materials and complies with USP Class VI, USDA standards, and 3-A sanitary standards, making it ideal for use in environments where hygiene is a priority. For product details, please visit our website. https://www.nitto-kinzoku.jp/archives/47690/ Product lineup: - PFA Sanitary Piping (Cynergy(R) Fittings) - PFA Sanitary Valves (Cynergy(R) Manual Valves)

-

[Technical Column] We have published "What is 'Flowability' that you should know when handling powder hoppers?"

The Nitto Metal Industry website has been updated with a new technical column. "What is 'flowability' that you should know when handling powder hoppers?" When a hopper used for feeding powder gets clogged or fails to discharge properly into the next process, it is often said that "the powder has poor flowability." But do you know what specific factors determine that "flowability"? This column provides a brief explanation of the factors that influence the flowability of powders. <Contents> 1. What is flowability? 2. Factors that affect flowability 3. How to improve flowability 4. You can actually experiment with the flow of powder and the angle and surface treatment of the hopper. For more details, visit: https://www.nitto-kinzoku.jp/archives/47385/ Technical column on stainless steel containers https://www.nitto-kinzoku.jp/tecnical-list/ This is a technical column on stainless steel containers explained by a top manufacturer that supplies "high-quality stainless steel containers" to the pharmaceutical industry. Please take a look.

-

[Custom Case] We have published a delivery case for a bio-related manufacturer.

This is a base used to insert a thin, special strip film delivered to a bio-related manufacturer, which is used for immersing it in a bath containing a liquid reagent. It is made of SUS316L material, which has excellent chemical resistance. The surface has been processed to be smooth to prevent damage to the film. For more details, please visit our website. https://www.nitto-kinzoku.jp/archives/product/1u011969/

-

We will exhibit at the Powder & Bulk Solids Exhibition Osaka 2019.

We are Nitto Metal Industry, a manufacturer of stainless steel containers and mixing devices. We will be exhibiting at the Powder Industry Exhibition to be held in October. At this exhibition, we will showcase stainless steel products related to powder handling. We will also present new products that will be unveiled for the first time, so please come and visit us. Date: October 16 (Wednesday) to 18 (Friday), 2019, from 10:00 to 17:00 Venue: Intex Osaka Booth Location: Hall 5, 5-C53

-

What are the reasons our stainless steel containers are chosen in the pharmaceutical industry?

We have renewed the content of the "Product Features" page on our company website. Our containers are particularly highly regarded in the pharmaceutical manufacturing process. We have a long history of supplying many mega-pharmaceutical companies, generic pharmaceutical companies, and health food manufacturers. Here, we address questions such as, "What kind of containers are stainless steel containers?" and "What makes Nitto Metal Industry's stainless steel containers different?"

-

[Custom Case] We have published a delivery case for a food manufacturer.

This is a hopper-type container equipped with a workbench for pouring powder from bags, which we supplied to a food manufacturer. To make it easier for women to work, the height of the workbench is kept within 800mm. The cover can be opened and closed halfway, preventing powder from flying up and foreign substances from mixing in during the pouring process. For more details, please visit our company website. https://www.nitto-kinzoku.jp/archives/46566/

-

[Technical Column] How can this chemical be stored? ~ The best packing for chemicals ~

Our company website "Technical Column" has been updated. "How should this chemical be stored? ~ The best packing for chemicals ~" The standard material for the packing that comes with our stainless steel containers is silicone. There are no issues with using silicone material when handling liquids like water. However, some chemicals do not interact well with silicone and can cause swelling. If the packing swells, it may deform and detach. To maintain the performance of the container, it is important to ensure compatibility between the chemicals being handled and the packing material. For more details, visit: https://www.nitto-kinzoku.jp/archives/45802/ Technical Column on Stainless Steel Containers: https://www.nitto-kinzoku.jp/tecnical-list/ This is a technical column on stainless steel containers explained by a top manufacturer that supplies "high-quality stainless steel containers" to the pharmaceutical industry. We have a wealth of technical information that will surely be helpful when selecting or introducing stainless steel containers! Please take a look.

-

Notice of Summer Vacation

We would like to express our sincere gratitude for your continued patronage of our stainless steel products. We regret to inform you that our summer holiday period will be as follows: 【Summer Holiday Period】 From Sunday, August 11, 2019, to Thursday, August 15, 2019. We will resume normal operations on Friday, August 16, 2019. Inquiries received during the holiday period will be addressed sequentially starting from Friday, August 16, 2019. We apologize for any inconvenience this may cause and thank you for your understanding.

-

We have pre-released a case study of our delivery to a pharmaceutical manufacturer on Facebook.

At Nitto Metal Industry, we are previewing custom-made case studies on Facebook every month. In this 33rd installment, we are introducing a custom-made product adopted by a pharmaceutical manufacturer: a "water tank for purified water supply" equipped with a stainless steel ball tap. Please take a look. For more details, visit here: https://www.facebook.com/nittokinzoku/

-

We will be exhibiting at "FOOMA JAPAN 2019 International Food Industry Exhibition."

We will be exhibiting at "FOOMA JAPAN 2019 International Food Industry Exhibition," showcasing products primarily focused on stainless steel containers and peripheral equipment such as mixers. We sincerely look forward to your visit. FOOMA JAPAN 2019 International Food Industry Exhibition Dates: July 9 (Tuesday) - 12 (Friday), 2019 Time: 10:00 AM - 5:00 PM Venue: Tokyo Big Sight Booth Location: West 4G-34 (West Exhibition Hall 4F)

-

Production Process Overview: The "Until the Stainless Steel Container Arrives" page has been renewed.

We have renewed the content of our company's website "Production Process Overview" page. Nitto Metal Industry is a manufacturer that consistently handles everything from the design to the production of stainless steel containers in-house. In particular, after welding, we use our original technology for processing, enhancing the value of our products. We will introduce how Nitto Metal Industry's stainless steel containers are made, step by step. Please take a look. For more details, visit here: https://www.nitto-kinzoku.jp/archives/44760/

-

[Technical Column] Stirring Experiment Case Study: Detergent vs. Stirrer that Suppresses Foaming

To investigate the performance of a centrifugal stirrer equipped with the E-REVO stirring element, which is designed to minimize air entrapment, we conducted an experiment by stirring a tank filled with water and detergent. The results showed that it significantly reduced foaming compared to a propeller stirrer. Please take a look. For more details, visit: https://www.nitto-kinzoku.jp/archives/44405/ Technical column on stainless containers: https://www.nitto-kinzoku.jp/tecnical-list/ This technical column on stainless containers is explained by a leading manufacturer that supplies "high-quality stainless containers" to the pharmaceutical industry. It contains a wealth of technical information that will surely be helpful when selecting or introducing stainless containers! We encourage you to take a look.

-

We will be exhibiting at "Interfex Japan 2019."

We will be exhibiting at "Interfex Japan 2019." We sincerely look forward to your visit. We will mainly showcase products that combine stainless steel containers and peripheral equipment such as mixers. Please come and visit us! Interfex Japan 2019 Dates: July 3 (Wednesday) - 5 (Friday), 2019 Time: 10:00 AM - 6:00 PM (ends at 5:00 PM on the last day) Venue: Tokyo Big Sight Booth Location: South Exhibition Hall 1F, Raw Material Processing Zone S1-16

-

[Technical Column] We compared the airtightness of sealed containers.

Among the inquiries we receive from customers, we often get the question, "Which type of sealed container has a higher sealing performance, the catch clip type or the lever band type?" In response to our customers' requests, we conducted an experiment to compare the sealing performance of these containers. Please take a look. For more details, visit here: https://www.nitto-kinzoku.jp/archives/technic/tank_sealing/ Technical column on stainless containers: https://www.nitto-kinzoku.jp/tecnical-list/ This is a technical column on stainless containers explained by a leading manufacturer that supplies "high-quality stainless containers" to the pharmaceutical industry. We have a wealth of technical information that will surely be helpful when selecting or introducing stainless containers! We encourage you to take a look.

-

We have added product videos to our company website.

A mixer used for blending contents. Many of them are inserted from the top of the container or fixed to the lid, but there are also "bottom mixers" that have blades installed at the bottom of the container, like a household blender. In this video, we introduce the features of bottom mixers using the MAG-NEOⓇ seal mixer model RBnt, highlighting the differences from conventional top-mounted mixers. For more details, visit: https://www.nitto-kinzoku.jp/archives/43591/

-

[Custom Case] We have published a delivery case for a packaging container manufacturer.

This is a versatile half-tapered container that we supplied to packaging container manufacturers, used widely as cleaning buckets, washbasins (for hand washing), and water baths (tanks). We have produced containers of 10L, 15L, and 20L. The customization features a lower height and a larger diameter compared to standard sizes of the same capacity. For more details, please visit our website. https://www.nitto-kinzoku.jp/archives/43454/

-

[Custom Case] We have published a delivery case for a plant equipment company.

This is a mesh cage delivered to a plant equipment company, used for filtration purposes (foreign matter removal). It has been manufactured in a size compatible with our sealed container [CTH-33]. Made entirely of stainless steel, it is resistant to rust and hygienic. For more details, please visit our website. https://www.nitto-kinzoku.jp/archives/43446/

-

New employees for the 2019 fiscal year have joined the company.

New employees for the fiscal year 2019 have joined the company. Nitto Kinzoku Industry will strive to create better products together with the newly added employees.

-

[Custom Case] We have published a delivery case for a powder equipment manufacturer.

This is a product that we customized for a powder equipment manufacturer, featuring an integrated sight glass [NMB] with a flange connection. In addition to the flange connection, we designed it to withstand vacuum conditions and changed the material of the gasket to enhance chemical resistance, making it a sight glass tailored to the customer's requirements. For more details, please visit our website. https://www.nitto-kinzoku.jp/archives/42526/

-

We have published a technical column titled "Does the Handle Make the Difference? What Makes a Stainless Steel Container Easy to Use."

Handles attached to containers. Have you ever found them difficult to grip or hard to clean? Just changing the handle can improve the usability of the container, so we offer customization not only for the container but also for the handles. This time, we will introduce the types of handles for stainless steel containers and recommend the most suitable handles based on our customers' requests and concerns. For more details, click here: https://www.nitto-kinzoku.jp/archives/technic/handle/

-

[Custom Case] We have published a delivery case for a pharmaceutical manufacturer.

This is a custom-made tray with a fluororesin coating on both the inner and outer surfaces, delivered to a pharmaceutical manufacturer. Typically, fluororesin coating is applied only to the inner surface that comes into contact with the contents, but in this product, it is also applied to the outer surface for corrosion prevention. For more details, please visit our website. https://www.nitto-kinzoku.jp/archives/42539/

-

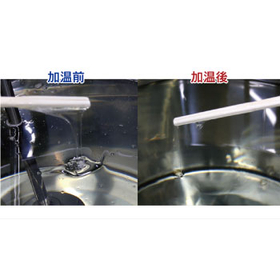

We have added a product video for the heater unit on our homepage.

We have published a product video of a heater unit that can heat and stir contents with just one device on our company website. We will show you how the water syrup inside the container is heated and stirred, reducing its viscosity. https://www.nitto-kinzoku.jp/archives/43248/

-

[Homepage] Added case studies of electric motor stirrers adopted by pharmaceutical manufacturers.

On the product page for the 【NTME】 electric motor stirrer, we have added "case studies" from pharmaceutical manufacturers who are actually using the product.

-

[Custom Case] We have published a delivery case for a chemical manufacturer.

This is a custom-made pre-foaming machine that we delivered to a chemical manufacturer. Due to the customer's concern that "the existing pre-foaming machine is made of iron and may rust," we manufactured it in an all-stainless steel specification that is less prone to rust. For more details, please visit our website. https://www.nitto-kinzoku.jp/archives/43134/