ポンプの予知保全

ポンプの予知保全

ポンプの予知保全において、状態基準保全(CBM)は最も効果的なカテゴリであり、その中核を担うのが振動監視です。この技術では、ポンプやモーター、軸受などの振動データをリアルタイムで収集・解析します。これにより、キャビテーション、軸のミスアライメント、インペラの損傷、ベアリングの劣化といった異常の兆候を、深刻な故障が発生するずっと前の初期段階で正確に捉えることができます。最適なタイミングでメンテナンスを行うことで、計画外の停止時間(ダウンタイム)と修理コストを大幅に削減し、ポンプの長寿命化と安定した流体供給能力を維持します。信頼性の高い設備管理と生産性向上に不可欠なアプローチです。

1~13 item / All 13 items

-

For abnormal detection of pump equipment! Easy maintenance with low-cost WiFi vibration sensors.

Don't miss abnormal vibrations in pumps! Easy monitoring with smartphones, achieving both labor reduction and increased operational efficiency.

last updated

-

For predictive maintenance of pump equipment! WiFi vibration sensor "Conan Air"

Early detection of abnormal vibrations and predictive maintenance! Achieving trouble avoidance and labor reduction through smartphone monitoring.

last updated

-

Ideal for monitoring vibrations in fan equipment! Compact vibration sensor with WiFi compatibility.

Immediate detection of abnormal vibrations in fans and blowers! Achieving operational stability and labor reduction through preventive maintenance.

last updated

-

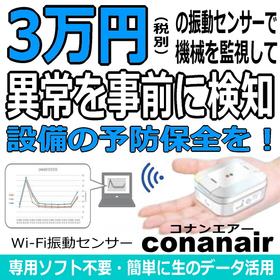

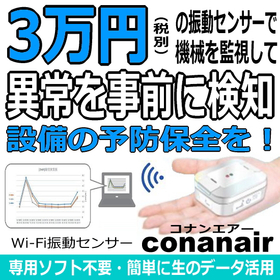

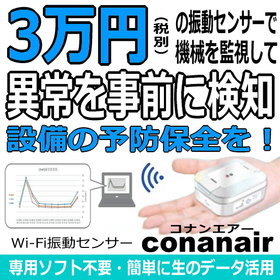

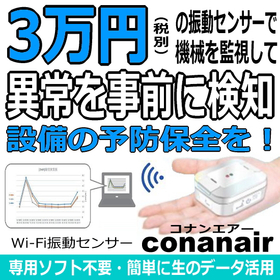

Affordable small Wi-Fi vibration monitor Conan Air for equipment predictive maintenance.

Achieve stable operation of equipment machinery while saving costs and time with the low-cost Wi-Fi vibration monitor "Conan Air," ideal for predictive maintenance!

last updated

-

Low-cost, compact Wi-Fi vibration sensor: Conan Air

Achieve stable operation of equipment and machinery while saving costs and time with the low-cost Wi-Fi vibration monitor "Conan Air," suitable for preventive maintenance!

last updated

-

Bearing abnormality detection technology for motors has been patented! Wireless vibration meter Conan Air.

Achieve stable operation of equipment machines while saving costs and time with the low-cost Wi-Fi vibration monitor "Conan Air," suitable for predictive maintenance!

last updated

-

Technology for detecting bearing abnormalities such as bearings has been patented! Conan Air.

Achieve stable operation of equipment and machinery while saving costs and time with the low-cost Wi-Fi vibration monitor "Conan Air," suitable for preventive maintenance!

last updated

-

Bearing abnormality detection patented - Wi-Fi vibration sensor "Conan Air"

Save costs and time with the low-cost Wi-Fi vibration monitor "Conan Air," suitable for preventive maintenance, to achieve stable operation of equipment and machinery!

last updated

-

Conan Air for Manufacturing: Early Detection of Equipment Abnormalities

Easy operation with a smartphone detects abnormal vibrations in machinery and prevents failures before they occur.

last updated

-

Conan Air for Building Management: Wi-Fi Vibration Sensor

Easy with your smartphone! Early detection of building equipment abnormalities to maintain a safe and secure environment!

last updated

-

Conan Air for Railway Vehicles: Detecting Abnormal Vehicle Vibrations

We monitor the vibrations of railway vehicles to prevent failures before they occur. It can be implemented at a low cost.

last updated

-

Conan Air for Wind Power Generation

Detects abnormal vibrations of the blades and supports stable operation of wind power generation equipment!

last updated

-

Conan Air for Food Processing Lines

Easy operation with a smartphone allows for early detection of abnormalities in food processing lines!

last updated