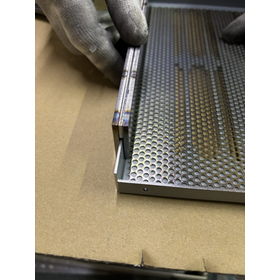

[VA/VE Case] Positioning Jig for Sheet Metal Parts

Improving quality precision and measures to prevent defective products! A case of creating a jig with chamfered corners that is inserted between the parts.

We would like to introduce a VA/VE case study of a positioning jig for sheet metal parts. In areas where the sheet metal parts needed to be perpendicular to the counterpart parts, they would slip underneath, leading to misalignment of the welding position and resulting in defects. Based on improvement suggestions from on-site workers, we created a jig with chamfered corners that clamps onto the counterpart parts, which helped prevent scratches during jig use and improved positioning accuracy. 【Case Overview】 ■Before - In areas where the sheet metal parts needed to be perpendicular to the counterpart parts, they would slip underneath, leading to misalignment of the welding position and resulting in defects. ■After - A jig with chamfered corners that clamps onto the counterpart parts was created. - This helped prevent scratches during jig use and improved positioning accuracy. *For more details, please download the PDF or feel free to contact us.

basic information

For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

catalog(2)

Download All CatalogsRecommended products

Distributors

【Strength 1】State-of-the-art machinery and equipment We focus particularly on blanking, bending, and welding, and by introducing the latest equipment such as laser-punch combination machines, automatic die exchange bending machines, and fiber laser robotic welding machines, we produce products with high precision and appearance quality. 【Strength 2】Integrated production system from design to processing to secondary processing to assembly We have established a one-stop production system that covers everything from design, material procurement, sheet metal processing, press processing, plating, painting, printing, to assembly. This integrated production system enables us to provide high-quality products at low prices. 【Strength 3】Production of varied types and quantities In addition to state-of-the-art equipment and an integrated production system, we promote factory IT through 3D-CAD design, parts development, production schedule formulation using production management systems, delivery management, progress tracking using tablets, paperless drawing access, and ensuring traceability, allowing us to handle a wide range of production from small quantities of various types to mass production. 【Strength 4】Cost reduction proposals through VE suggestions Utilizing the technology accumulated over 70 years and 3D-CAD, we consider optimal materials, plate thicknesses, and processing methods from the design stage and propose VE (Value Engineering) suggestions.