Featured products

Products/Services(2items)

news list

-

Notice of Participation in the 8th [Nagoya] Smart Factory EXPO

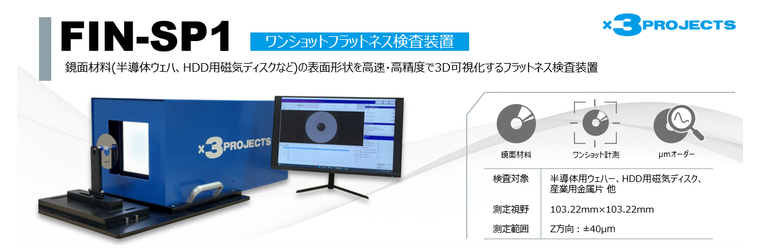

We are pleased to announce that we will be exhibiting at the "8th [Nagoya] Smart Factory EXPO," which will be held at Portmesse Nagoya from October 29 (Wednesday) to October 31 (Friday), 2025. At our booth, we will introduce a flatness measurement device that enables high-speed and high-precision 3D visualization of the surface shapes of mirror materials (such as semiconductor wafers and magnetic disks for semiconductor HDDs), along with live demonstrations of the actual equipment. This is a valuable opportunity to experience the performance and usability of our products firsthand, so please be sure to stop by our booth [N42-9]. We sincerely look forward to your visit.

-

Announcement of the release of the automatic visual inspection device "Surf-In"

"Surf-In" is an all-in-one model of an appearance inspection device that integrates lighting equipment, imaging equipment, conveying mechanisms, and processing devices. A multi-joint robot is positioned appropriately according to the shape of the workpiece being inspected, and our original SSMM method, which is suitable for inspecting products with mirror-like surfaces (such as painted or plated surfaces), ensures that even the smallest defects are not overlooked. ■ Achieves suitable inspections corresponding to the surface condition of the target workpiece ■ Capable of detecting defects without being affected by orange peel on painted surfaces ■ Detected defects: bumps, scratches, peeling, stains, scale, distortion ■ Minimum detectable defect size: 0.3 mm ■ Inspectable size: 300(W) mm × 300(H) mm × 200(D) mm ■ A suitable solution for inspecting a variety of complex shapes.

-

Our inspection unit SSMM-1R has been adopted by the "Nissan Intelligent Factory."

On October 8, 2021, Nissan Motor Co., Ltd. unveiled the production line of its Tochigi plant, which has adopted Nissan's unique car manufacturing concept, "Nissan Intelligent Factory," to support next-generation vehicle production with innovative manufacturing technology and contribute to achieving carbon neutrality. As part of this concept, our inspection unit "SSMM-1R" was selected for automatic inspection of the painted exterior.

-

Surface Defect Inspection Unit "SSMM-1R" Catalog Renewal Announcement

We have renewed the catalog for our surface defect inspection unit "SSMM-1R." In this renewal, we clearly introduce the strengths and unique technologies of our inspection system, along with case studies that include photographs.

-

It was published in the January issue of Image Lab.

The January issue of Image Lab features a case study on "Surface Defect Inspection Units Using Slit Lighting." It introduces examples of the implementation of our inspection units in the automotive industry's inspection processes and new initiatives. If you would like more detailed information, please contact us, and we will send you the published article. Media Name: Image Lab (Published by Japan Industrial Publishing) Publication Date: January 10, 2021 P.69 - "Case Study of Surface Defect Inspection Units Using Slit Lighting"

Aboutバイスリープロジェクツ

Vice Leap Projects Co., Ltd. provides total solutions for systems, from hardware to software.

Vice Leap Projects is engaged in contracted development of software and hardware. We assist in solving various challenges using our unique technology and know-how.