PTFE-modified polyethylene wax additive CERAFLOUR 999

Ultrafine PTFE-modified polyethylene wax additive CERAFLOUR 999

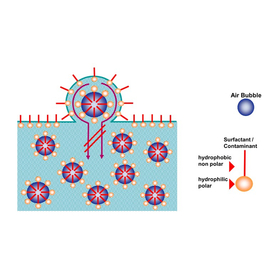

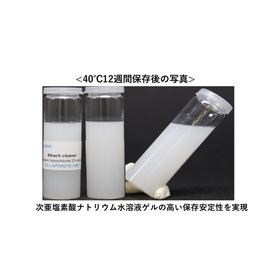

The new CERAFLOUR 999 is a wax with a very fine and uniform particle distribution. This additive is not simply a mixture of soft polyethylene and relatively hard PTFE, but is co-milled using BYK's novel manufacturing process. The resulting wax additive improves the scratch resistance and abrasion resistance of the coating film while also achieving a smooth surface. Various additional effects can be achieved, such as high gloss and high transparency, a soft touch tactile effect, or a slight matte effect.

basic information

Features • Significantly improved scratch resistance and abrasion resistance • Ultra-fine wax particles evenly distributed • Ideal for thin film coatings • Excellent leveling properties and reduced COF values • Maintains gloss and transparency in most solvent systems • Slightly matte finish possible in water-based systems • Widely usable in water-based, solvent-based, solvent-free, and UV systems • Easy to add • Approved for food contact applications Compliant with EU REACH General Properties • Ultra-fine, powdered PTFE-modified polyethylene wax additive • Melting point: 115 °C • 100% active ingredient • Form: fine powder • Particle size distribution: D50: 4 μm, D90: 9 μm

Price information

Please contact us.

Delivery Time

Applications/Examples of results

Applicable fields • General industrial coatings • Coil coatings • Can coatings • Wood and furniture coatings • Architectural coatings • Powder coatings • Printing inks

Recommended products

Distributors

BYK Japan KK is engaged in the import, wholesale, and technical service of paints, additives, and measuring instruments. As a leading supplier of functional additives and testing equipment across various application fields, we provide solutions to assist you in product development and solving challenges. Please feel free to contact us if you have any inquiries.