BYK Powder Coating Process Additive (Appearance Enhancer)

BYK powder coating process additives contribute to labor-saving in the paint manufacturing process and are highly effective in improving appearance (haze, gloss, leveling) and degassing properties.

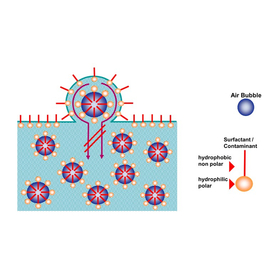

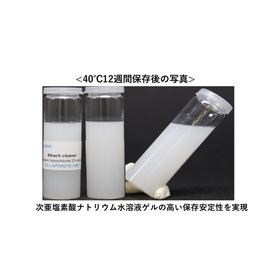

BYK powder coating process additives BYK-3950 P, BYK-3951 P, and BYK-3955 P contribute to labor-saving in the paint manufacturing process and are very effective in improving appearance (haze, gloss, leveling) and enhancing degassing properties. Expected effects from the application of process additives: - High concentration of pigments and fillers - Improved appearance (haze, gloss, leveling) - Reduced melt viscosity during curing - Simplification of the extruder process - Enhanced degassing properties For improving degassing properties in primid-based powder coatings, we recommend wax additives CERAFLOUR 960 and CERAFLOUR 964. - CERAFLOUR 964 enhances degassing properties without adversely affecting gloss (non-blooming). It is very suitable for glossy powder coatings and is particularly ideal for dark-colored applications where visible surface defects are likely to occur. Its low melting point also makes it optimal for low-temperature curing systems (LT systems).

basic information

【Additives for Powder Coatings】 BYK-3950 P: General-purpose grade, effective for all resin types. Melting point 86°C. BYK-3951 P: Effective for inorganic pigments/fillers such as titanium dioxide. Reduces melt viscosity during curing. BYK-3955 P: Improves color acceptance and leveling of carbon black. 【Wax Additives for Powder Coatings】 CERAFLOUR 960: Standard type. Improves wetting and leveling of pigments. Melting point: 145°C, average particle size (D50): 4μm. CERAFLOUR 964: For low-temperature curing systems, rapidly effective due to low melting point during extrusion and curing. No blooming effects. Melting point: 75°C, average particle size (D50): 20μm.

Price information

Please contact us.

Delivery Time

Applications/Examples of results

Practical examples; samples separately. - Improvement of gloss and haze BYK-3951 P: Confirmation of effects through the mixing formulation of pigments and fillers Polyester resin/Primid system Formulation 30% TiO2 + Filler 25% - Improvement of degassing properties BYK-3955 P: Epoxy/Acrylate hybrid system (70:30)

catalog(6)

Download All Catalogs

News about this product(1)

Recommended products

Distributors

BYK Japan KK is engaged in the import, wholesale, and technical service of paints, additives, and measuring instruments. As a leading supplier of functional additives and testing equipment across various application fields, we provide solutions to assist you in product development and solving challenges. Please feel free to contact us if you have any inquiries.