Release agent for metal die casting HORDAMER PE 02

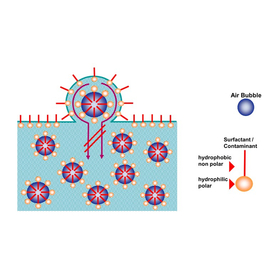

Optimal formulation components for water-based mold release agents used in aluminum die casting. It is used in a wide range of applications.

HORDAMER PE 02: - Release agent primary polyethylene dispersion for metal die casting - Improvement of surface protection for water-based care products and adhesion strength of emulsion adhesives - Anti-caking (anti-clumping) agent for thermoplastic resins and hot melt adhesives - Wetting dispersant for thermoplastic color masterbatches

basic information

HORDAMER PE 02 Product Data Primary polyethylene dispersion containing anionic emulsifiers Density (20 °C): 0.97 g/ml Non-volatile content: 40 % Carrier: Water Melting point (wax component): 95 °C Viscosity (20 °C): 20 mPa·s pH (20 °C): 8-12

Price information

Please contact us for the price.

Delivery Time

Model number/Brand name

BYK

Applications/Examples of results

Applicable Fields - Release agents for metal die casting - Hot melt adhesives - Adhesives for packaging - Features for thermoplastic plastic applications Pellet materials made from thermoplastic resins (TPE, TPU, EVA) tend to solidify and cake (stick) under pressure and heat. By using HORDAMER PE 02 to pelletize the aforementioned resins in water, a protective layer is formed around the pellets, resulting in a non-sticky, freely flowing granular material. Unlike solid release agents (chalk, talc) that typically generate a large amount of dust from pellet materials, the amount of additives can be significantly reduced, thus avoiding any adverse effects on the physical properties of thermoplastic resins. Dust generation during processing can also be eliminated. - Care products and polishing agents

catalog(5)

Download All Catalogs

News about this product(1)

Recommended products

Distributors

BYK Japan KK is engaged in the import, wholesale, and technical service of paints, additives, and measuring instruments. As a leading supplier of functional additives and testing equipment across various application fields, we provide solutions to assist you in product development and solving challenges. Please feel free to contact us if you have any inquiries.