LAPONITE as an antistatic agent

All LAPONITE products have conductivity and can be used for static electricity prevention.

Recommended products: LAPONITE-RDS, LAPONITE-JS, LAPONITE-S 482, and LAPONITE-SL 25. All LAPONITE products have conductivity and can be used for static electricity prevention. The LAPONITE sol grade is easy to apply as a high-concentration, low-viscosity dispersion, making it particularly useful for the purpose of anti-static treatment.

basic information

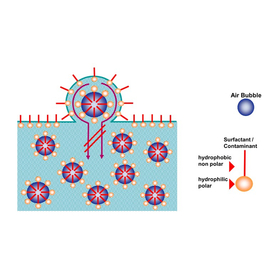

There are two areas where LAPONITE is used as an antistatic agent. One is the manufacturing of antistatic products such as paper, glass, and polymer films. A dispersion of LAPONITE is applied to create a coating layer on the material so that an antistatic film is formed on the surface of the product. The final product resulting from this process is typically classified as antistatic grade material. The standard usage amount is a coating weight of 1g.m-2 to 5g.m-2. The other area is functioning as an aid in processes. Manufacturing processes that involve handling small particle size materials (such as paper fibers or plant seeds) in dry environments tend to accumulate static electricity. This can lead to undesirable phenomena where particles agglomerate together or adhere to surfaces inside processing equipment and on packaging materials. To dissipate this static charge and allow dry particles to flow freely during the process, LAPONITE is added to the system. The final product obtained from this process is usually not classified as an antistatic material. The standard usage amount is 0.1% to 1.0% relative to the total dry mass of the materials involved in the process.

Price information

Please contact us for the price.

Delivery Time

Model number/Brand name

BYK

Applications/Examples of results

Applicable Fields Applications/substrates where LAPONITE can be used as an antistatic agent include the following: Thermal transfer media, paper, polymer films, polymer fibers, materials, non-woven fabrics Packaging materials for electronics, specialty printing paper Electronic copies, antistatic polishing base paper Photo media, processing of paper fibers Polymer packaging films, leather processing Glass sheets and fibers, seed processing

catalog(7)

Download All Catalogs

Recommended products

Distributors

BYK Japan KK is engaged in the import, wholesale, and technical service of paints, additives, and measuring instruments. As a leading supplier of functional additives and testing equipment across various application fields, we provide solutions to assist you in product development and solving challenges. Please feel free to contact us if you have any inquiries.