LAPONITE in anti-static grinding base paper

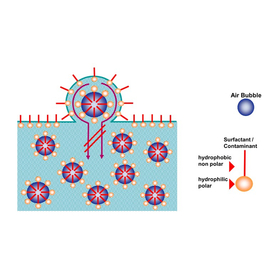

LAPONITE is a film-forming material that can form a smooth and dense coating layer on a wide range of substrates without the addition of a binder.

Advantages of using LAPONITE for antistatic coatings: 1. LAPONITE films conduct electricity through two independent mechanisms: ► Ionic - partially affected by humidity. ► Electronic - not affected by humidity. Overall, the conductivity of LAPONITE coatings is less influenced by changes in relative humidity in the surrounding environment compared to coatings made with cationic or anionic polymer resins. 2. LAPONITE coatings do not re-dissolve and are suitable for overcoating with either aqueous or solvent-based coating formulations. 3. LAPONITE films are suitable for use with writing, printing, or solvent or water-based adhesives. 4. LAPONITE films possess gas barrier and blocking prevention properties. 5. LAPONITE coatings do not discolor over time or when heated. 6. Paper coated with LAPONITE can be easily reprocessed.

basic information

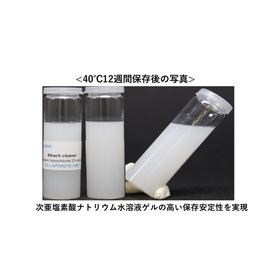

Guideline formulation: This simple formulation is suitable for producing an antistatic coating on abrasive paper. Ingredients Weight % Water 82 LAPONITE-JS 18 Add LAPONITE powder to water while stirring rapidly, and continue mixing for 30 minutes before adding the following: Acrylic emulsion resin (packaging) 7.2 Typical resins are usually supplied with an active ingredient content of 50%, and with this addition amount, the LAPONITE pigment to binder ratio will be 100:20. Suitable binders include Primal TR407 (Dow) and Acronal S305D (BASF). Stir until homogeneous. If necessary, additives such as biocides and viscosity control agents may be added. The formulation can be applied immediately or stored for several weeks before application. Viscosity: <20s Ford Cup after 424 hours.

Price information

Please contact us for the price.

Delivery Time

Model number/Brand name

BYK

Applications/Examples of results

Applications of LAPONITE products in the paper industry: - Antistatic coating for specialty industrial paper, fine particle retention aid - Antistatic packaging for electrical components and consumer electronic products - High surface area ink receiving layer for inkjet printing - Rheology control of coating colors - Barrier coating conductive layer for electrophotographic paper

catalog(6)

Download All Catalogs

Recommended products

Distributors

BYK Japan KK is engaged in the import, wholesale, and technical service of paints, additives, and measuring instruments. As a leading supplier of functional additives and testing equipment across various application fields, we provide solutions to assist you in product development and solving challenges. Please feel free to contact us if you have any inquiries.