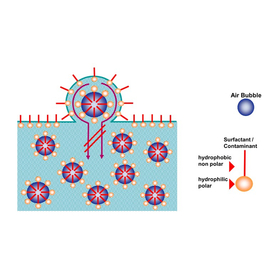

Wet dispersants for uniform dispersion of pigments and fillers.

Surface wetting of pigments and fillers preferentially, loosening agglomerates, preventing re-agglomeration, and achieving uniform dispersion and stabilization.

BYK-MAX P Series: Wetting Dispersant for Thermoplastic Plastics Improving productivity and appearance in the production of colorants, functional compounds, and masterbatches! ● Enhances the wettability of matrix resins on the surfaces of pigments and fillers, solving the following issues: - Decreased color development and extrudability due to secondary agglomerates (mesh filter clogging) - Lack of surface appearance due to insufficient wetting - Functional expression of difficult-to-disperse fillers such as carbon nanotubes (CNT) ● Can be used during compounding with pre-dispersion or drive blending ● Can be used in conjunction with general-purpose dispersants such as metal soaps

basic information

【BYK-MAX P 4102】 Heat resistance stability ~300℃ 【BYK-MAX P 4101】 Heat resistance stability <250℃ 【BYK-MAX D 4221】 Heat resistance stability ~250℃

Price information

We also have free samples available. Please feel free to inquire.

Delivery Time

Model number/Brand name

BYK-MAX P Series

Applications/Examples of results

Purpose: Improvement of coloring properties and productivity of plastic colorants (masterbatches) - Functional masterbatches and compounds with high filling of inorganic fillers - Olefin compounds with carbon nanotubes (CNT) that are difficult to disperse - Suppression of venting up due to mesh clogging by foreign substances during material recycling, etc.

catalog(3)

Download All CatalogsRecommended products

Distributors

BYK Japan KK is engaged in the import, wholesale, and technical service of paints, additives, and measuring instruments. As a leading supplier of functional additives and testing equipment across various application fields, we provide solutions to assist you in product development and solving challenges. Please feel free to contact us if you have any inquiries.