BYK additives applicable to prevent material separation in underwater mortar.

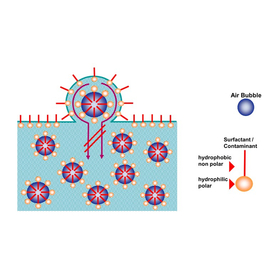

Additives that solve the issues of underwater mortar: Adapted to prevent material separation, improving workability by adjusting viscosity and enhancing foaming.

Recommended Additives ◆Viscosity Adjusting Agents OPTIBENT-602: Modified/Active Bentonite (Powder Type) OPTIGEL-WX: Modified/Active Bentonite (Powder Type) ◆Defoamers BYK-1691 SD: Mixture of Polyether Adsorbed on a Carrier (Powder Type) BYK-1693 SD: Mixture of Plant Oil and Polyether Adsorbed on a Carrier (Powder Type) ◆Wetting and Dispersing Agents DISPERBYK-2290: Mixture of Surfactants and Inorganic Carrier (Powder Type)

basic information

OPTIBENT-602【General Properties】 pH (2 %): Approximately 9-11 Bulk Density: 700-900 kg/m³ Moisture Content: Maximum 14 % Appearance: Flowable beige powder

Price information

Please contact us.

Delivery Time

Model number/Brand name

OPTIBENT-602、OPTIGEL-WX、BYK-1691 SD、BYK-1693 SD、DISPERBYK-2290

Applications/Examples of results

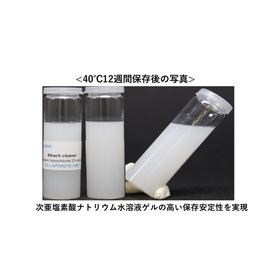

By simply adding it to underwater non-separating mortar, which can be easily repaired underwater and exhibits high strength and durability, it becomes possible to control the viscosity of cement and mortar-based fillers in areas with high moisture content. Depending on the type of additive, it is also possible to increase viscosity or reduce viscosity, and by improving fluidity, the filling ability in narrow gaps is enhanced. Additionally, by eliminating bubbles, workability and finish quality are further improved.

catalog(3)

Download All Catalogs

Recommended products

Distributors

BYK Japan KK is engaged in the import, wholesale, and technical service of paints, additives, and measuring instruments. As a leading supplier of functional additives and testing equipment across various application fields, we provide solutions to assist you in product development and solving challenges. Please feel free to contact us if you have any inquiries.