No metal leaching! PTFE self-automated detachable valve [ALL-PTFE connector]

High cleaning performance! The internal structure is very simple with no fluid retention areas! No metal leaching!

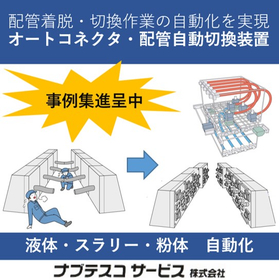

■What is an ALL-PTFE Connector? An ALL-PTFE connector features an internal valve that is integrally molded from PTFE, ensuring that the sliding parts during the opening and closing of the internal valve are isolated from the wetted parts, preventing product contamination. It is particularly suitable for lines following sterilization processes where maintaining a sterile condition is crucial. This product pursues the functions required in manufacturing equipment in this field (safety, cleanability, durability) while also being compact and lightweight. Additionally, since all wetted parts, including the internal valve, are made of PTFE, there is no leaching of metal ions into the process fluids, making it suitable for equipment used with chemicals such as wafer cleaning solutions and substrate coatings in the semiconductor field. ■Features of Nabtesco Service's ALL-PTFE Connector High cleanability ⇒ The internal structure is very simple, with no areas for fluid retention. No need for localized SIP in the shaft ⇒ The internal valve opening and closing mechanism is completely isolated from the wetted parts. Elimination of contamination ⇒ A unique fixation method is employed that prevents bypassing around sealing components. Usable for fluids that are sensitive to metal ion leaching ⇒ Since all wetted parts are made of PTFE, there is no leaching of metal ions. Excellent maintainability ⇒ Achieved compactness and lightweight design compared to conventional valves of the same size.

basic information

Due to the absence of metal ion leaching, it is used in the semiconductor industry for automatic connection and disconnection of cleaning solutions. PTFE has high corrosion resistance to strong acids such as hydrochloric acid, which is why it is used in the automatic switching of piping in the chemical industry.

Price range

Delivery Time

Applications/Examples of results

■Specifications Drive Method: Normally Closed Pneumatic Drive Wetted Parts Material: PTFE *O-ring material can be selected at will Applicable Fluids: Various process fluids / Inert gases Applicable Fluid Temperature: 0 to 100℃ (provided there is no freezing) Maximum Cleaning Temperature: 143℃ (Steam / Hot water at 0.5MPa or less) Operating Pressure: Normal 0.6MPa (Body pressure resistance 1.0MPa) Minimum Passage Cross-Sectional Area: At least the cross-sectional area of the connecting piping Durability of Internal Valve Opening and Closing: 20,000 cycles (Passed internal durability test of 100,000 cycles) (Continuous operation durability count at clean water to 150℃ steam, 0.2 to 0.5MPa) Operating Air Pressure: 0.4MPa

Related Videos

catalog(6)

Download All CatalogsRecommended products

Distributors

Nabtesco Service Co., Ltd. was established in February 1971 as a 100% subsidiary of Japan Air Brake Co., Ltd. (later Nabco Co., Ltd., now Nabtesco Corporation) with the aim of providing sales services for air brake parts for commercial vehicles. Today, it operates in a wide range of fields, from automobiles, railways, and ships to construction machinery, industrial machinery, and even environmental equipment, engaging in the design, manufacturing, sales, maintenance, and repair of various products, including pneumatic equipment, hydraulic equipment, and electronic devices. The core of Nabtesco Service's business is the design, development, manufacturing, maintenance, and servicing of key parts that support the safety and operation of industrial society, including brakes for automobiles and railway vehicles, control valves for construction machinery, and auto connectors, auto couplers, and couplers used in factory production lines. Its mission is to provide high-quality services quickly and reliably. Based on the technology and know-how cultivated over the years, Nabtesco Service aims to establish a system that delivers products in the shortest possible time and a nationwide service network, striving to provide high-quality services swiftly and reliably while supporting societal safety and contributing to industrial development.