Automating the hose switching operation on the wax manufacturing line.

Contributing to SDGs through improved production efficiency, elimination of connection errors, eradication of hazardous work, and reduction of cleaning water usage.

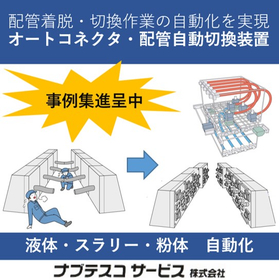

We have automated the switching operation of hoses (piping) in the blending process for wax manufacturing. We have produced an automatic piping switching device (straight type) for 9 upstream systems and 2 downstream systems. 【Benefits of Implementation】 ■ Automation leads to reduced labor hours and improved production efficiency. ■ Damage caused by connection errors, which occurred every year, has decreased from an annual average of 4 million yen to 0 yen. ■ Burns to workers from steam and hot water during connection and disconnection tasks have been eliminated, removing hazardous work. ■ Continuous cleaning has become possible, significantly reducing the annual water usage for cleaning.

basic information

We will design and manufacture tailored solutions according to your equipment situation. Please consult with us first.

Price range

Delivery Time

Applications/Examples of results

Fine chemical plant Chemical plant Pharmaceutical and intermediate plant Seasoning plant Food plant Sake brewing plant Others

Related Videos

catalog(7)

Download All CatalogsRecommended products

Distributors

Nabtesco Service Co., Ltd. was established in February 1971 as a 100% subsidiary of Japan Air Brake Co., Ltd. (later Nabco Co., Ltd., now Nabtesco Corporation) with the aim of providing sales services for air brake parts for commercial vehicles. Today, it operates in a wide range of fields, from automobiles, railways, and ships to construction machinery, industrial machinery, and even environmental equipment, engaging in the design, manufacturing, sales, maintenance, and repair of various products, including pneumatic equipment, hydraulic equipment, and electronic devices. The core of Nabtesco Service's business is the design, development, manufacturing, maintenance, and servicing of key parts that support the safety and operation of industrial society, including brakes for automobiles and railway vehicles, control valves for construction machinery, and auto connectors, auto couplers, and couplers used in factory production lines. Its mission is to provide high-quality services quickly and reliably. Based on the technology and know-how cultivated over the years, Nabtesco Service aims to establish a system that delivers products in the shortest possible time and a nationwide service network, striving to provide high-quality services swiftly and reliably while supporting societal safety and contributing to industrial development.