Automatic connection and disconnection device for power supply of shape steel mill in a steelworks (Auto Joint)

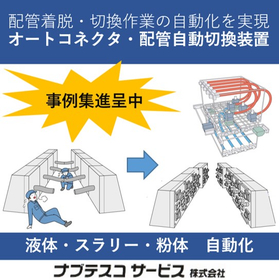

We will automate the complicated pin attachment and detachment tasks in a 3K environment. It is of course also possible to incorporate hydraulic fluid, lubricants, air, and Ar gas simultaneously, in addition to electricity.

Operating a steelmaking facility requires a tremendous amount of electricity. Due to the high current flow, manually connecting electrical pins is highly dangerous, and the large number of connections makes it difficult to shorten the time for attachment and setup. Nabtesco Service's automatic attachment and detachment devices (auto connectors, auto couplers, auto joints) enable bulk attachment and detachment by arranging these electrical pins on the panel.

basic information

Automatic Disconnect Device (Auto Connector, Auto Coupler, Auto Joint) / Examples of Manufacturing Achievements for Rolling Mills Core Deviation Tolerance: Horizontal Direction: ±20mm Vertical Direction: ±10mm Connection Direction: ±5mm Inclination: 1/150 Connection Wiring: Power Line: Φ16 - 16 strands, 440V / 340A Power Line: Φ12 - 8 strands, 440V / 230A Control Power: Φ5 - 186 strands, 440V / 85A Control Signal: Φ2.4 - 480 strands, 160V / 25A Dustproof: Automatic opening and closing cover during connection and disconnection *The above is just an example. We will manufacture customized products according to the customer's specifications.

Price range

Delivery Time

Applications/Examples of results

We also offer an automatic attachment and detachment device (auto connector, auto joint) for hot rolling mills that implements vibration and dust countermeasures.

Related Videos

catalog(5)

Download All CatalogsRecommended products

Distributors

Nabtesco Service Co., Ltd. was established in February 1971 as a 100% subsidiary of Japan Air Brake Co., Ltd. (later Nabco Co., Ltd., now Nabtesco Corporation) with the aim of providing sales services for air brake parts for commercial vehicles. Today, it operates in a wide range of fields, from automobiles, railways, and ships to construction machinery, industrial machinery, and even environmental equipment, engaging in the design, manufacturing, sales, maintenance, and repair of various products, including pneumatic equipment, hydraulic equipment, and electronic devices. The core of Nabtesco Service's business is the design, development, manufacturing, maintenance, and servicing of key parts that support the safety and operation of industrial society, including brakes for automobiles and railway vehicles, control valves for construction machinery, and auto connectors, auto couplers, and couplers used in factory production lines. Its mission is to provide high-quality services quickly and reliably. Based on the technology and know-how cultivated over the years, Nabtesco Service aims to establish a system that delivers products in the shortest possible time and a nationwide service network, striving to provide high-quality services swiftly and reliably while supporting societal safety and contributing to industrial development.