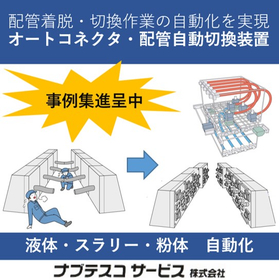

Automating the attachment and detachment work of the SUS powder line in steelmaking equipment!

Automated the piping assembly and disassembly work for the ceramic powder line.

■Before Implementation When repairing the inner walls (refractory bricks) of the converter within the steelworks, workers manually performed piping work on-site to supply repair ceramics and combustion gas. This work was conducted in a high-temperature environment, making it dangerous. ■After Implementation It has become possible to automatically and continuously supply repair ceramics and combustion gas on-site, leading to improved work efficiency, enhanced working conditions, and increased safety. Operations can now be conducted even with powders that are difficult to transport due to automatic attachment and detachment, as well as gases that require immediate detection of external leaks. In powder transfer, metal components can wear down and damage the inner surfaces of pipes, so ceramic linings are being installed.

basic information

We offer custom solutions ranging from individual connectors to entire systems based on your equipment situation. Please feel free to consult with us first.

Price range

Delivery Time

Applications/Examples of results

Powder line

Related Videos

catalog(5)

Download All CatalogsRecommended products

Distributors

Nabtesco Service Co., Ltd. was established in February 1971 as a 100% subsidiary of Japan Air Brake Co., Ltd. (later Nabco Co., Ltd., now Nabtesco Corporation) with the aim of providing sales services for air brake parts for commercial vehicles. Today, it operates in a wide range of fields, from automobiles, railways, and ships to construction machinery, industrial machinery, and even environmental equipment, engaging in the design, manufacturing, sales, maintenance, and repair of various products, including pneumatic equipment, hydraulic equipment, and electronic devices. The core of Nabtesco Service's business is the design, development, manufacturing, maintenance, and servicing of key parts that support the safety and operation of industrial society, including brakes for automobiles and railway vehicles, control valves for construction machinery, and auto connectors, auto couplers, and couplers used in factory production lines. Its mission is to provide high-quality services quickly and reliably. Based on the technology and know-how cultivated over the years, Nabtesco Service aims to establish a system that delivers products in the shortest possible time and a nationwide service network, striving to provide high-quality services swiftly and reliably while supporting societal safety and contributing to industrial development.