Piping automatic switching device - rotary type

It is optimal for the liquid transfer lines of cleaning and sanitizing (CIP/SIP) systems in food and beverage factories.

With precise positioning control driven by a stepping motor, you can automatically switch connections by simply specifying the connection joint Bn on the control panel and pressing the execute button. This is optimal for switching one system to multiple lines. It can be manufactured at a lower cost compared to multi-type and straight-type options. - Lubricating oil manufacturing process - Fine chemical process - Alcohol manufacturing process - Food manufacturing process - Beverage manufacturing process - Pharmaceutical raw material input process - Pharmaceutical synthesis process - Semiconductor manufacturing process - Toothpaste manufacturing process - Others

basic information

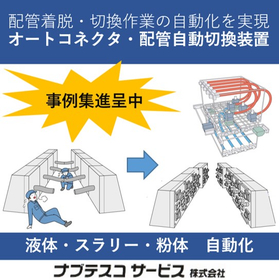

The rotary type automatic piping switching device is an automatic switching device for fluid piping that enables switching from one to many pipes. It is particularly suitable for liquid transfer lines in cleaning and sterilization (CIP/SIP) systems in food and beverage factories. ■ Benefits of Implementation ◎ Increases work efficiency compared to manual switching! ◎ Eliminates the need for attachment and detachment work in explosive areas, as well as dangerous substances like hot water and hydrochloric acid, freeing workers from hazardous tasks! ◎ Allows for seamless switching compared to automatic valves and valve units, reducing waste liquid, food loss, and cleaning solution, contributing to SDGs! ◎ Eliminates cross-contamination! ◎ Space-saving design! ◎ Reduces the need for preventive maintenance of seals compared to automatic valves and valve units, lowering running costs! ◎ Pigging system installation is also possible!

Price range

Delivery Time

Model number/Brand name

Piping Automatic Switching Device <Rotary Type>

Applications/Examples of results

Especially food and beverage factories (cleaning and sanitizing systems)

Related Videos

catalog(9)

Download All CatalogsRecommended products

Distributors

Nabtesco Service Co., Ltd. was established in February 1971 as a 100% subsidiary of Japan Air Brake Co., Ltd. (later Nabco Co., Ltd., now Nabtesco Corporation) with the aim of providing sales services for air brake parts for commercial vehicles. Today, it operates in a wide range of fields, from automobiles, railways, and ships to construction machinery, industrial machinery, and even environmental equipment, engaging in the design, manufacturing, sales, maintenance, and repair of various products, including pneumatic equipment, hydraulic equipment, and electronic devices. The core of Nabtesco Service's business is the design, development, manufacturing, maintenance, and servicing of key parts that support the safety and operation of industrial society, including brakes for automobiles and railway vehicles, control valves for construction machinery, and auto connectors, auto couplers, and couplers used in factory production lines. Its mission is to provide high-quality services quickly and reliably. Based on the technology and know-how cultivated over the years, Nabtesco Service aims to establish a system that delivers products in the shortest possible time and a nationwide service network, striving to provide high-quality services swiftly and reliably while supporting societal safety and contributing to industrial development.