[Improvement Case] Introduction of an oil recovery device reduces coolant replacement costs.

We will introduce a case where the labor of changing cutting oil has been eliminated, significantly improving work efficiency!

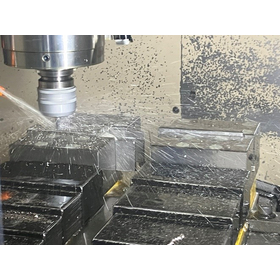

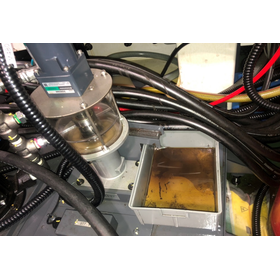

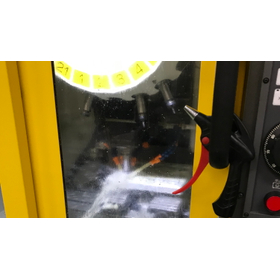

We would like to introduce a case from a company in Niigata Prefecture that uses water-soluble cutting oil in their machining process. Due to contamination from oil, the coolant deteriorated in about a year, and the degradation of the oil caused a decline in the working environment, prompting a request for improvement. Upon inspecting the equipment, we found that the cause of the decay and stickiness was the existing belt-type oil skimmer, which was too dirty to recover the lubricant effectively. We proposed the introduction of a floating oil recovery device that uses a special filter for higher recovery rates. With the introduction of the floating oil recovery device, the coolant was cleaned in a short time, and the frequency of coolant replacement was extended from once a year to once every two years. 【Background of Introduction】 - Contamination from other oils from the equipment was unavoidable, and while the existing oil skimmer was in use, recovery was not satisfactory, leading to coolant deterioration in about a year due to the contamination. - The factory became smelly due to the decay of the oil, and with a predominantly female workforce, there were many complaints, making the improvement of the working environment urgent. *For more details, please download the PDF or feel free to contact us.*

basic information

**Effects After Implementation** ■ The introduction of the oil recovery device has resulted in the coolant becoming clean in a short time, allowing the replacement of coolant to be extended from once a year to once every two years. ■ Since it can be completely separated from water and processed as a valuable material, it has led to cost savings. ■ The coolant remains in a state close to new even after a long time, with no occurrence of foul odors or stickiness, improving the working environment and eliminating complaints from female employees. ■ The lifespan of the coolant has been extended, and the replacement costs have been halved compared to before the device was introduced, resulting in an annual cost reduction of 150,000 yen. ■ The elimination of the hassle of changing cutting oil has significantly improved work efficiency. *For more details, please download the PDF or feel free to contact us.*

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

catalog(2)

Download All CatalogsRecommended products

Distributors

Nagaoka Oil Co., Ltd. was founded in 1940 and has developed a business that covers the entire spectrum of industrial lubricants, from providing industrial lubricants and cutting oils to the collection and recycling of waste fluids. Leveraging its characteristics as a trading company, it responds to customer needs with precision by sourcing a variety of industrial lubricants and related products from multiple manufacturers. In addition to providing services based on the know-how accumulated as professionals in industrial lubricants and cutting oils, it supports the entire production technology in the field of industrial lubricants.