【課題解決】事例紹介

【課題解決】事例紹介

各テーマによる課題解決事例です。

1~30 item / All 38 items

-

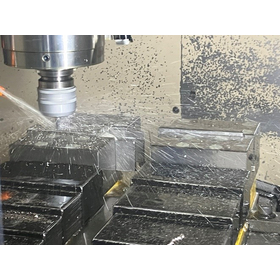

[Improvement Case] Introduction of Low Mist Type Water-Soluble Cutting Oil for Improved Work Environment

We would like to introduce a case where we received feedback from the operators saying, "The mist has decreased, and the smell has become less than before!"

last updated

-

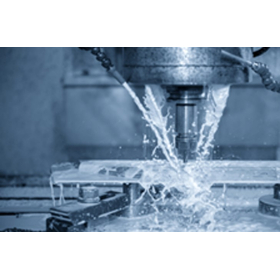

[Improvement Case] Significant reduction of oil mist with only the change of non-water-soluble cutting oil.

We will introduce a case where the oil mist visibly decreased, significantly reducing the adherence and stickiness to workers' hair and clothing!

last updated

-

[Improvement Case] Increased recovery rate of other oils and reduction of cutting oil odor.

We will introduce a case where the separation of the sliding surface oil improved, leading to an increased recovery rate of the oil skimmer, resulting in reduced odors and the elimination of stickiness!

last updated

-

[Improvement Case] Successfully removed mold and odor by changing cutting oil.

We will introduce a case where removing the sliding surface oil maintained the liquid state and prevented the occurrence of mold and odors!

last updated

-

[Improvement Case] By implementing ideas during the exchange, the lifespan of cutting oil increased from 6 months to over 1 year.

We will introduce a case where the work time per machine, which used to take 2 hours, has been reduced to 1 hour!

last updated

-

[Improvement Case] Switching to cutting oil with a longer fluid life to reduce costs.

We will introduce a case where the service life of cutting oil was extended to more than twice, reducing waste liquid treatment costs and labor expenses!

last updated

-

[Improvement Case] Introduction of an oil recovery device reduces coolant replacement costs.

We will introduce a case where the labor of changing cutting oil has been eliminated, significantly improving work efficiency!

last updated

-

[Improvement Case] Prevention of spoilage and odor in water-soluble cutting oil

Introducing a case where the foul odor at the site has disappeared, resulting in a clean working environment!

last updated

-

[Improvement Case] Achieved zero cost for cleaning agent replacement while improving the work environment.

We will introduce a case where, even after more than a year since the liquid was changed, no mold or scum has occurred, and the cleaning power has been maintained!

last updated

-

[Improvement Case] Introduction of water-soluble cutting oil with excellent defoaming properties.

We will introduce a case where reviewing the defoaming performance of the coolant has eliminated overflow even when the tank is filled to capacity!

last updated

-

[Improvement Case] Introduced additives to improve foam issues with alkaline cleaning agents.

We will introduce a case where the usage of cleaning agents and defoamers, which were frequently replenished, was reduced, leading to cost savings!

last updated

-

[Improvement Case] Combination of Low Foaming Oil Agent and Foam-Resistant Rust Preventive Liquid

We will introduce examples where the elimination of tasks such as machine stoppages and cleaning around tanks has contributed to improvements in production efficiency!

last updated

-

[Improvement Case] Preventing foaming of water-soluble cutting oil and reducing coolant usage.

We will introduce examples of improvements in production efficiency due to the elimination of cleaning and replenishment tasks!

last updated

-

[Improvement Case] Solving Foaming and Rust Issues with Alkaline Cleaners

Introducing a case where issues with rust formation and overflow caused by cleaning agents foaming have been eliminated!

last updated

-

[Improvement Case] Reduced costs and effort associated with equipment maintenance cleaning.

We will introduce a case where the need for paid cleaning through outsourcing has been eliminated, achieving a total cost reduction of 1/10!

last updated

-

[Improvement Case] Achieved reduction of warm-up time in winter and noise reduction during startup.

We will introduce a case where workers no longer need to come in earlier than scheduled, leading to an improvement in the work environment!

last updated

-

[Improvement Case] Successfully reduced electricity consumption by switching grease.

We will introduce a case where we successfully reduced electricity usage by about 8% while performing our usual operations!

last updated

-

[Improvement Case] Achieved a 25% price reduction per drum compared to the new liquid price.

We will introduce a case that achieved an operational performance of about 50% waste liquid recovery rate every month!

last updated

-

[Improvement Case] Suppressing discoloration of water-soluble cutting oil and improving production efficiency.

This leads to a significant improvement in production efficiency, keeping the machining room and windows of the machines in a clean condition.

last updated

-

[Improvement Case] Selection of Suitable Oil Eliminates Discoloration of Aluminum Material

There are white stains on the processed surface! There were no defects due to discoloration or stains, and difficult-to-cut materials were processed without any issues.

last updated

-

[Improvement Case] Reviewing rust prevention oil to improve plating defects in the subsequent process.

Selected a rust preventive oil with excellent washability! A case where plating has become cleaner than before.

last updated

-

[Improvement Case] Selection of lubricants suitable for processing conditions to prevent discoloration of copper.

Reduced labor and costs associated with post-processing cleaning! The range of materials that can be processed has expanded.

last updated

-

[Improvement Case] Elimination of rust on products occurring after processing with water-soluble cutting oil.

The amount of dirt entering the rust prevention oil has decreased, allowing us to extend the replacement cycle of the rust prevention oil!

last updated

-

[Improvement Case] Increased Work Efficiency and Reduced Use of Rust Preventive Oil

Production efficiency improves without compromising rust prevention effectiveness! Usage can be reduced to approximately one-third.

last updated

-

[Improvement Case] Eliminating Rust Caused by Sweat Attachment

Reduction of time and costs spent on rust removal! An example of improved production efficiency.

last updated

-

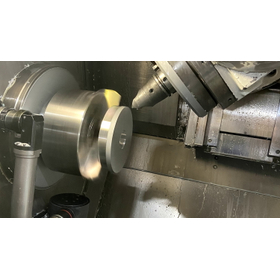

[Improvement Case] Changed cutting oil, significantly improved surface accuracy.

The surface accuracy has improved to the point that it is visibly noticeable! It contributes to increased production efficiency from many aspects.

last updated

-

[Improvement Case] Switching processing oils in response to the revision of the REACH regulations.

Achieving satisfactory processing accuracy and tool life! A case where a lubricant compliant with REACH regulations was found.

last updated

-

[Improvement Case] Solving the warping problem of products occurring in deep hole machining.

A warp has occurred in the product! Here is an introduction to a case where the warp issue was resolved and power consumption was also reduced.

last updated

-

[Improvement Case] Eliminating Burn Marks Occurring in Grinding Processing

The whetstone is clogged, causing burns on the product! Even after three years since its introduction, it remains a clear, transparent liquid.

last updated

-

[Improvement Case] Using the appropriate oil agent for processing conditions increased mold life by five times.

Mold life extended! A case where the burden on operators was reduced and machine downtime was also minimized.

last updated