[Improvement Case] Selection of lubricants suitable for processing conditions to prevent discoloration of copper.

Reduced labor and costs associated with post-processing cleaning! The range of materials that can be processed has expanded.

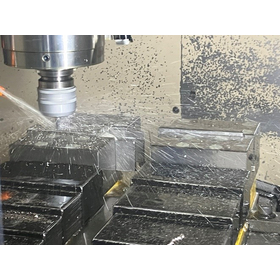

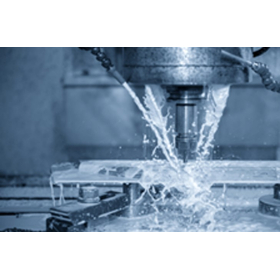

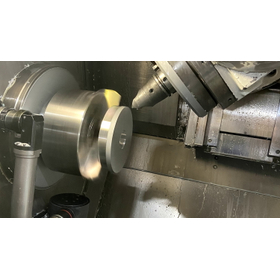

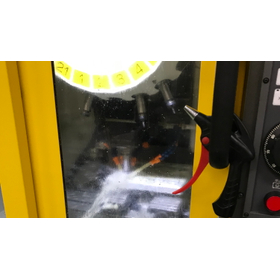

We would like to introduce a case where a company engaged in general cutting processing in Niigata Prefecture consulted us about selecting the appropriate oil agent to prevent discoloration of copper and stickiness of cutting oil. The company faced a problem where products were discolored after processing copper for new projects. To suppress the discoloration of copper caused by cutting oil, they were washing the products with a parts cleaner to prevent discoloration. After implementation, the copper no longer discolored after processing, eliminating the need to use the parts cleaner, which allowed them to reduce the labor involved in cleaning and save approximately 20,000 yen annually in costs. 【Case Summary】 ■Challenges - Processing copper resulted in discoloration of the material and discoloration and stickiness of water-soluble cutting oil, leading to inefficient production. ■Implementation Effects - Prevented discoloration of copper and discoloration and stickiness of cutting oil, reducing the labor and costs associated with product cleaning and cutting oil replacement. *For more details, please download the PDF or feel free to contact us.

basic information

For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

catalog(2)

Download All CatalogsRecommended products

Distributors

Nagaoka Oil Co., Ltd. was founded in 1940 and has developed a business that covers the entire spectrum of industrial lubricants, from providing industrial lubricants and cutting oils to the collection and recycling of waste fluids. Leveraging its characteristics as a trading company, it responds to customer needs with precision by sourcing a variety of industrial lubricants and related products from multiple manufacturers. In addition to providing services based on the know-how accumulated as professionals in industrial lubricants and cutting oils, it supports the entire production technology in the field of industrial lubricants.