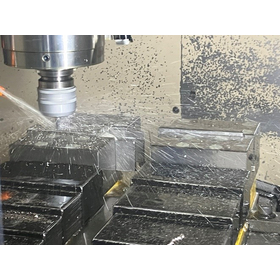

切削油・研削油

切削油・研削油

⽔溶性切削油・研削油、不⽔溶性切削油・研削油

1~27 item / All 27 items

-

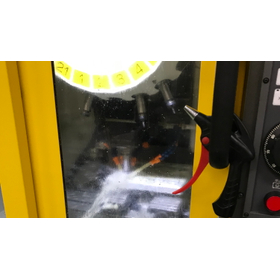

[Improvement Case] Developed a dedicated oil for non-water-soluble cutting oil, improving the working environment.

Developed a dedicated oil for Category 4 petroleum! The mist that floats in the factory during the opening and closing of machine windows has also decreased.

last updated

-

[Improvement Case] Significant reduction in oil mist with only a change in non-water-soluble cutting oil.

Contributes to reducing the working environment and usage through low mist generation! Enables reliable oil supply to processing points.

last updated

-

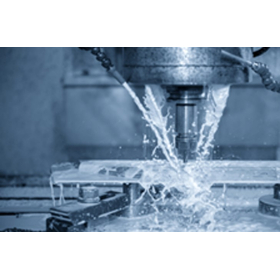

[Improvement Case] Introduction of Low Mist Type Water-Soluble Cutting Oil

Mist reduction! The cutting oil in the tank is less likely to decrease, and the amount of coolant used is also reduced.

last updated

-

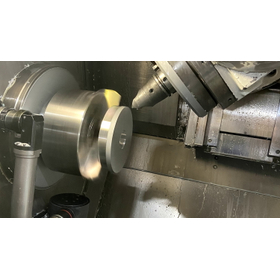

[Improvement Case] Changed cutting oil, significantly improved surface accuracy.

The surface accuracy has improved to the point that it is visibly noticeable! It contributes to increased production efficiency from many aspects.

last updated

-

[Improvement Case] Elimination of rust on products occurring after processing with water-soluble cutting oil.

The amount of dirt entering the rust prevention oil has decreased, allowing us to extend the replacement cycle of the rust prevention oil!

last updated

-

[Improvement Case] Suppressing discoloration of water-soluble cutting oil and improving production efficiency.

This leads to a significant improvement in production efficiency, keeping the machining room and windows of the machines in a clean condition.

last updated

-

[Improvement Case] Preventing foaming of water-soluble cutting oil and reducing coolant usage.

We will introduce examples of improvements in production efficiency due to the elimination of cleaning and replenishment tasks!

last updated

-

[Improvement Case] Introduction of water-soluble cutting oil with excellent defoaming properties.

We will introduce a case where reviewing the defoaming performance of the coolant has eliminated overflow even when the tank is filled to capacity!

last updated

-

[Improvement Case] Prevention of spoilage and odor in water-soluble cutting oil

Introducing a case where the foul odor at the site has disappeared, resulting in a clean working environment!

last updated

-

[Improvement Case] Switching to cutting oil with a longer fluid life to reduce costs.

We will introduce a case where the service life of cutting oil was extended to more than twice, reducing waste liquid treatment costs and labor expenses!

last updated

-

[Improvement Case] By implementing ideas during the exchange, the lifespan of cutting oil increased from 6 months to over 1 year.

We will introduce a case where the work time per machine, which used to take 2 hours, has been reduced to 1 hour!

last updated

-

[Improvement Case] Successfully removed mold and odor by changing cutting oil.

We will introduce a case where removing the sliding surface oil maintained the liquid state and prevented the occurrence of mold and odors!

last updated

-

[Improvement Case] Increased recovery rate of other oils and reduction of cutting oil odor.

We will introduce a case where the separation of the sliding surface oil improved, leading to an increased recovery rate of the oil skimmer, resulting in reduced odors and the elimination of stickiness!

last updated

-

[Improvement Case] Significant reduction of oil mist with only the change of non-water-soluble cutting oil.

We will introduce a case where the oil mist visibly decreased, significantly reducing the adherence and stickiness to workers' hair and clothing!

last updated

-

[Improvement Case] Introduction of Low Mist Type Water-Soluble Cutting Oil for Improved Work Environment

We would like to introduce a case where we received feedback from the operators saying, "The mist has decreased, and the smell has become less than before!"

last updated

-

[Patent Granted] Effortlessly replace machine tool coolant with Ringer Flash.

Just add 1% concentration of coolant one week before changing the machine tool coolant!

last updated

-

Lingaflash, a cleaning additive for machine tools using cutting oil for watch manufacturing.

Improved cutting oil management in precision machining for watch manufacturing with the patented "Ringer Flash." Just add 1% one week before replacing water-soluble cutting oil!

last updated

-

Efficiently replace cutting oil with Ringer Flash for agricultural machinery.

With the patented "Ringer Flash," reduce the hassle and time of changing cutting oil in agricultural machinery! Just add 1% one week before replacing water-soluble cutting oil!

last updated

-

Ringer Flash, a cleaning additive for machine tools using cutting oil for semiconductor manufacturing.

Thoroughly clean semiconductor manufacturing machinery effortlessly with the patented "Ringer Flash." Just add 1% one week before changing the water-soluble cutting oil!

last updated

-

Cleaning Additive for Machine Tools 'Ringer Flash' for Machine Tool Manufacturers

Thoroughly clean machine tools effortlessly with the patented "Ringer Flash." Just add 1% one week before changing water-soluble cutting oil!

last updated

-

Linga Flash Cleaning Additive for Machine Tools Using Cutting Oil for Electronic Components

Thoroughly clean machine tools for electronic components effortlessly with the patented "Ringer Flash." Just add 1% one week before changing water-soluble cutting oil!

last updated

-

Linger Flash: Cleaning Additive for Machine Tools Using Cutting Oil for Precision Machinery

Thorough cleaning of precision machine tools with the patented "Ringer Flash." Just add 1% one week before changing water-soluble cutting oil!

last updated

-

【For molds】 Cutting oil longevity enhancement with the machine cleaning additive Ringer Flash.

Thoroughly clean mold machinery effortlessly with the patented "Ringer Flash." Just add 1% one week before changing water-soluble cutting oil!

last updated

-

Extending the lifespan of cutting oil for machine tools with Linger Flash for medical devices.

With the patented "Ringer Flash," thoroughly clean machine tools used in medical device manufacturing without hassle. Just add 1% one week before changing water-soluble cutting oil!

last updated

-

Maintaining the Precision of Machine Tools with Ring Flash for Aerospace Applications

With the patented "Ringer Flash," thoroughly clean machine tools effortlessly and support the precision of aerospace component processing.

last updated

-

Water-soluble cutting oil cleaning agent for the automotive industry: Ringer Flash

Thoroughly clean machine tools effortlessly with the patented "Ringer Flash." Just add 1% one week before changing water-soluble cutting oil!

last updated

-

[Industrial Lubricating Oil Troubleshooting News] Streamlining Coolant Replacement

Improving the efficiency of coolant replacement work! Just "add a cleaning agent" before refilling to reduce odors and dirt!

last updated