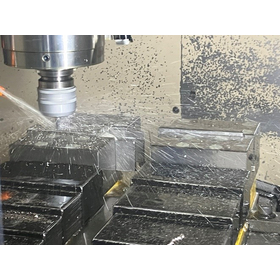

[Improvement Case] Prevention of spoilage and odor in water-soluble cutting oil

Introducing a case where the foul odor at the site has disappeared, resulting in a clean working environment!

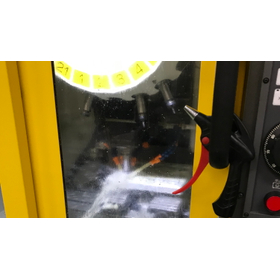

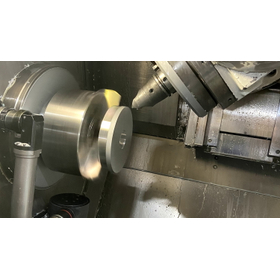

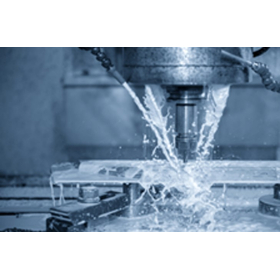

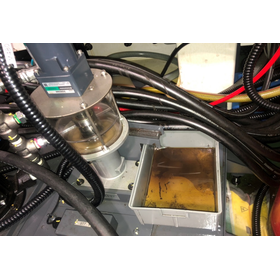

We received a request from a foundry processing company in Nagano Prefecture regarding the issue of water-soluble cutting oil deteriorating within six months, leading to a worsening work environment and frequent rust problems with the products. We proposed using a "micro-emulsion" type cutting oil developed for foundry processing to address the customer's challenges. Additionally, we decided to implement regular concentration management of the cutting oil and conduct usage liquid analysis every three months. By selecting the appropriate oil based on the processing requirements and providing support for oil management, we achieved a result where the water-soluble cutting oil, which previously deteriorated within six months of replacement, remained intact without any deterioration even after five years. [Challenges Before Implementation] - Various types of water-soluble cutting oils had been used traditionally, but all deteriorated within six months, resulting in a constant foul odor in the workplace. - The machines had to be stopped twice a year, incurring significant costs for extensive cutting oil replacement work. - The deterioration of the cutting oil led to a decline in performance, causing rust to form on the processed products. *For more details, please download the PDF or feel free to contact us.*

basic information

【Effects After Introduction】 ■ No decay even after 5 years, remaining unchanged ■ The foul odor at the site has disappeared, creating a clean working environment ■ No more stickiness inside and outside the machinery, and issues with rust occurrence have improved ■ Achieved an annual cost reduction of approximately 900,000 yen *For more details, please download the PDF or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please download the PDF or feel free to contact us.

catalog(2)

Download All CatalogsRecommended products

Distributors

Nagaoka Oil Co., Ltd. was founded in 1940 and has developed a business that covers the entire spectrum of industrial lubricants, from providing industrial lubricants and cutting oils to the collection and recycling of waste fluids. Leveraging its characteristics as a trading company, it responds to customer needs with precision by sourcing a variety of industrial lubricants and related products from multiple manufacturers. In addition to providing services based on the know-how accumulated as professionals in industrial lubricants and cutting oils, it supports the entire production technology in the field of industrial lubricants.