Extending the lifespan of cutting oil for machine tools with Linger Flash for medical devices.

With the patented "Ringer Flash," thoroughly clean machine tools used in medical device manufacturing without hassle. Just add 1% one week before changing water-soluble cutting oil!

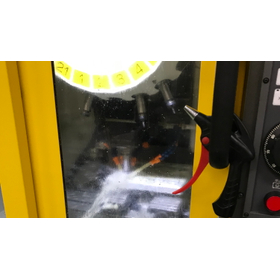

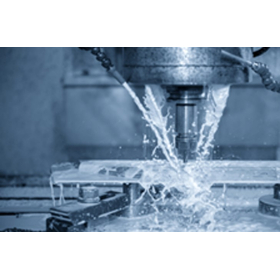

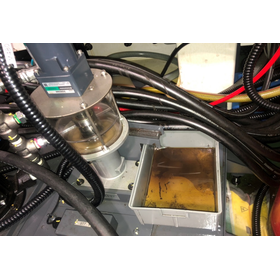

In the medical device industry, the stable operation of machine tools used in manufacturing is crucial to ensure the quality and safety of products. Lingaflash is a flushing additive effective against dirt and odors that adhere to machine tools and tanks using water-soluble cutting oil. It is added before the complete replacement of cutting oil and circulates to clean the dirt inside the machine tools, tanks, and piping. Processing can continue without stopping the machinery even after the additive is added. This reduces the time required for washing the tank during cutting oil replacement, thereby decreasing the amount of waste liquid. Moreover, from the perspective of chemical risk assessment, it does not fall under GHS classification criteria. It extends the lifespan of the water-soluble cutting oil after replacement, leading to increased productivity. [Recommended for such sites] - Want to shorten the flushing work during the replacement of water-soluble cutting oil. - Looking for a flushing agent that does not fall under GHS classification criteria from the perspective of chemical risk assessment. - In response to labor shortages and work style reforms. [Usage scenarios] - During the replacement of water-soluble cutting oil in the manufacturing of medical device parts. - During regular maintenance of medical device manufacturing factories. [Effects of introduction] - Extension of cutting oil lifespan. - Reduction of effort, working time, and waste liquid during cleaning.

basic information

Water-soluble cutting oil machine cleaning flushing additive 【Features】 - Easy to use: Processing can continue without stopping the machinery after addition. - Cleaning: Thoroughly cleans the coolant tanks and piping of machines, removing sludge and verdigris from castings. - Low odor and low irritation. - Usable for both ferrous and non-ferrous metals. - Reduces waste liquid volume and working time: Decreases the time needed for tank cleaning, thus reducing waste liquid volume. - Extends the lifespan of new cutting oil. - Not classified under GHS criteria. - Non-applicable under the PRTR law. - Patent obtained: Patent No. 7714861 for the flushing method. 【Usage Instructions】 - Please refer to the usage video available in the "Related Videos" section below. - Refer to the SDS when using. 【Our Strengths】 Nagaoka Oil Co., Ltd. provides optimal products and services tailored to customer needs as experts in industrial lubricants. We support customers in solving their challenges with a consistent support system from product provision to consulting and waste liquid treatment.

Price range

Delivery Time

Model number/Brand name

Lube Labo

Applications/Examples of results

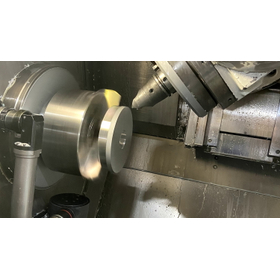

<Usage> Cleaning agent for machine tools | Flushing additive for replacing water-soluble cutting oil (coolant) in machine tools <Example Case 1> - Manufacturing: Machine parts processing - Products: Industrial machine parts - Work material: FCD (ductile cast iron), SC (carbon steel for machine structures) - Processing details: Outer diameter and inner diameter turning - Equipment used: NC lathe - Needs: The tank and liquid become dirty during FCD processing, taking time to clean <Example Case 2> - Manufacturing: Metal parts manufacturer - Products: Various machine parts - Work material: Castings - Processing details: Cutting, turning - Equipment used: Machining center, NC lathe - Needs: Cleaning of casting dirt, addressing odor from water-soluble cutting oil <Example Case 3> - Manufacturing: Aluminum parts manufacturer - Products: Aircraft parts, automotive parts - Work material: Aluminum - Processing details: Machining - Equipment used: Machining center - Needs: Looking for an additive that does not fall under GHS classification, with low irritation and odor <Packaging: Three sizes available> - Poly 2L - Poly 5L - Cubitainer 20L <Choosing packaging and usage amount> - For a 200L water-soluble cutting oil tank, use 2L of this product at 1% of 200L.

Related Videos

catalog(2)

Download All CatalogsRecommended products

Distributors

Nagaoka Oil Co., Ltd. was founded in 1940 and has developed a business that covers the entire spectrum of industrial lubricants, from providing industrial lubricants and cutting oils to the collection and recycling of waste fluids. Leveraging its characteristics as a trading company, it responds to customer needs with precision by sourcing a variety of industrial lubricants and related products from multiple manufacturers. In addition to providing services based on the know-how accumulated as professionals in industrial lubricants and cutting oils, it supports the entire production technology in the field of industrial lubricants.