news list

211~231 item / All 231 items

-

(Surface Grinding) Sludge Recovery Success Case 1 (Achieved High Sludge Recovery Capability and Reduced Maintenance Costs!)

With high sludge recovery capability, we have successfully achieved a significant reduction in maintenance costs! (Excerpt) 1. Background of Introduction - We were using magnetic separators from other companies, but all of them wore out the magnetic drum and rubber in less than a year, becoming nothing more than accessories. I had almost given up thinking that this was the extent of magnetic separator capabilities... 2. Effects After Introduction - After a one-year trial period, I became convinced that this was an excellent product... ★ For more details, please be sure to check the "case study materials"! ☆ We can provide proposals based on usage conditions and installation environments in collaboration with the manufacturer.

-

(Surface Grinding) Sludge Recovery Success Case 2 (Achieved zero liquid replacement operation for 7 years with a low failure rate!)

The failure rate is low. We developed our own coolant purification system, achieving zero liquid replacement operation for 7 years! (Excerpt) 1. Background of Implementation - In order to build a factory trusted by customers, we focused on creating dry floor surfaces, establishing a clean factory, and promoting zero waste liquid activities. As part of this initiative, we conducted a comparison of the dewatering performance of magnetic separators... 2. Effects After Implementation - Thanks to the optimization of the arrangement of magnets, we are able to recover abrasive particles along with magnetic sludge, and the dewatering is very effective, with a moisture content below 30%... ★ For more details, please be sure to check the "Case Study Materials"! ☆ In collaboration with the manufacturer, we can provide proposals based on usage conditions and installation environments.

-

Shining Notification! Introduction to the "Lamp Tag Storage Management System"

The "lamp tags" attached to "shelf racks" and "flat-stored items" will illuminate to indicate their location. - "Which shelf is the 'material' for shipment on?" - "Which one is the 'cargo' that has arrived?" Such situations still exist in many workplaces. The "lamp tag location management system" that we are introducing this time allows anyone to easily and instantly identify the target "materials" or "cargo," significantly reducing the time spent searching. When the barcode on the "shipping instruction sheet" is scanned with a device, the "location address" is displayed on the device's screen, and at the same time, the "lamp tag" for the shipping materials lights up to indicate its location. The "lamp tag location management system" is perfect for "shelf rack management" and "flat storage management," and we hope you will take a look at our catalog.

-

"Palette Management System" Information Document

You can manage "Shipping / Unreturned" in a list with the "Palette / Management System"! ❶ Issuance of "QR Labels" ❷ Read at the time of shipping with a "device" ❸ Manage "Shipping / Unreturned" in a list on a "PC" ★ Excel integration is also possible * "QR Code" is a registered trademark of DENSO WAVE INCORPORATED.

-

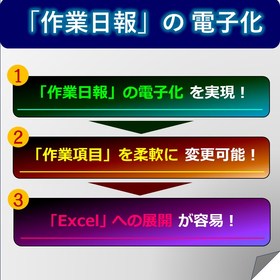

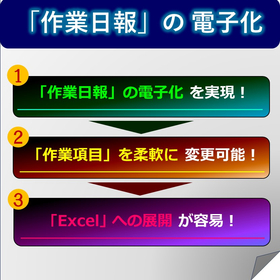

We will support the "digitization" of the "work report"!

The "work daily report" is an important foundational data for improving "standard work/standard time." We will support you in transitioning from "handwritten" to "electronic data"! ❶ Achieve the digitization of the "work daily report" ❷ Flexibly change "work items" ❸ Easy to expand and utilize in "Excel" * We would be grateful if you could consult us regarding the "digitization/systematization of various handwritten forms."

-

Shining Notification! Introduction to the "Lamp Tag Storage Management System"

The "lamp tags" attached to "shelf racks" and "flat-stacked items" will light up to indicate their location. - "Which shelf is the 'material' for shipment on?" - "Which one is the 'cargo' that has arrived?" Such scenarios still exist in many workplaces. The "lamp tag location management system" that we are introducing this time allows anyone to easily and instantly identify the target "materials" or "cargo," significantly reducing the time spent searching. When the barcode on the "shipping instruction" is scanned with a device, the "location address" is displayed on the device's screen, and at the same time, the "lamp tag" for the shipping materials lights up to indicate its location. The "lamp tag location management system" is perfect for "shelf rack management" and "flat-stacked management," and we hope you will take a look at our catalog.

-

We will support the "digitization" of the "work daily report"!

The "work daily report" is an important foundational data for improving "standard work/standard time." We will support you in transitioning from "handwritten" to "electronic data"! ❶ Achieve the digitization of "work daily reports" ❷ Flexibly change "work items" ❸ Easy expansion and utilization in "Excel" * We would be grateful if you could consult us regarding the "digitization/systematization of various handwritten forms."

-

Shining Notification! Introduction to the "Lamp Tag Storage Management System"

The "lamp tags" attached to "shelf racks" and "flat-stored items" will light up to indicate their location. - "Which shelf is the 'material' for shipment on?" - "Which one is the 'cargo' that has arrived?" Such situations still exist in many workplaces. The "lamp tag location management system" that we are introducing this time allows anyone to easily and instantly identify the target "materials" or "cargo," significantly reducing the time spent searching. When the barcode on the "shipping instruction" is scanned with a device, the "location address" is displayed on the device's screen, and at the same time, the "lamp tag" for the shipping materials lights up to indicate its location. The "lamp tag location management system" is perfect for "shelf rack management" and "flat storage management," and we hope you will take a look at our catalog.

-

Shining Notification! Introduction to the "Lamp Tag Storage Management System"

The "lamp tags" attached to "shelf racks" and "flat-stacked goods" will illuminate to indicate their location. - "Which shelf is the 'material' for shipping on?" - "Which one is the 'cargo' that has arrived?" Such scenes still exist in many workplaces. The "lamp tag location management system" that we are introducing this time allows anyone to easily and instantly identify the target "materials" or "cargo," significantly reducing the time spent searching. When the barcode on the "shipping instruction sheet" is scanned with a device, the "location address" is displayed on the device's screen, and at the same time, the "lamp tag" for the shipping materials lights up to indicate its location. We hope you will take a look at the catalog for the "lamp tag location management system," which is perfect for "shelf rack management" and "flat-stacked management."

-

We will support the "digitization" of the "work daily report"!

The "work report" is an important foundational data for improving "standard work/standard time." We will support you in transitioning from "handwritten" to "electronic data"! ❶ Achieve the digitization of "work reports" ❷ Flexibly change "work items" ❸ Easy expansion and utilization in "Excel" * We would be grateful if you could consult us regarding the "digitization/systematization" of various "handwritten forms."

-

Shining Notification! Introduction to the "Lamp Tag Storage Management System"

The "lamp tags" attached to "shelf racks" and "flat-stored items" will light up to indicate their location. - "Which shelf is the 'material' for shipment on?" - "Which one is the 'cargo' that has arrived?" Such scenes still exist in many workplaces. The "lamp tag location management system" that we are introducing this time allows anyone to easily and instantly identify the target "materials" or "cargo," significantly reducing the time spent searching. When the barcode of the "shipping instruction" is scanned with a device, the "location address" is displayed on the device's screen, and at the same time, the "lamp tag" for the shipping materials lights up to notify you. The "lamp tag location management system" is perfect for "shelf rack management" and "flat storage management," and we hope you will take a look at our catalog.

-

We will support the "digitalization" of the "work report"!

The "work report" is an important foundational data for improving "standard work/standard time." We will support you in transitioning from "handwritten" to "electronic data"! ❶ Achieve the digitization of "work reports" ❷ Flexibly change "work items" ❸ Easy expansion and utilization in "Excel" * We would be grateful if you could consult us regarding the "digitization/systematization of various handwritten forms."

-

Shining Notification! Introduction to the "Lamp Tag Storage Management System"

The "lamp tags" attached to "shelf racks" and "flat-stored items" will light up to indicate their location. - "Which shelf is the 'material' for shipment on?" - "Which one is the 'cargo' that has arrived?" Such situations still exist in many workplaces. The "lamp tag location management system" that we are introducing this time allows anyone to easily and instantly identify the target "materials" or "cargo," significantly reducing the time spent searching. When the barcode on the "shipping instruction sheet" is scanned with a device, the "location address" is displayed on the screen, and at the same time, the "lamp tag" for the shipping materials lights up to indicate its location. The "lamp tag location management system" is perfect for "shelf rack management" and "flat storage management." We hope you will take a look at our catalog.

-

We will support the "digitization" of the "work daily report"!

The "work report" is an important foundational data for improving "standard work/standard time." We will support you in transitioning from "handwritten" to "electronic data"! ❶ Achieve the digitization of "work reports" ❷ Flexibly change "work items" ❸ Easy expansion and utilization in "Excel" * We would be grateful if you could consult us regarding the "digitization/systematization of various handwritten forms."

-

We will support you in converting handwritten "work reports" into electronic data!

The "work report" is an important foundational data for improving "standard work/standard time." We will support you in transitioning from "handwritten" to "digital data" to enhance productivity!

-

Shining Notification! Introduction to the "Lamp Tag Storage Management System"

The "lamp tags" attached to "shelf racks" and "flat-stacked goods" will light up to indicate their location. - "Which shelf is the 'material' for shipment on?" - "Which one is the 'cargo' that has arrived?" Such situations still exist in many workplaces. The "lamp tag location management system" that we are introducing this time allows anyone to easily and instantly identify the target "materials" or "cargo," significantly reducing the time spent searching. When the barcode on the "shipping instruction" is scanned with a device, the "location address" is displayed on the device's screen, and at the same time, the "lamp tag" for the shipping materials lights up to indicate its location. The "lamp tag location management system" is perfect for "shelf rack management" and "flat-stacking management," and we hope you will take a look at our catalog.

-

Introducing what can be done with Power Apps and examples of smartphone app development.

A new case of developing an app using "PowerApps" has been registered. "Power Apps," provided by Microsoft, allows you to create "mobile apps" by arranging pre-prepared components or using formulas and macros in a way similar to "Excel." By utilizing "Power Apps" to create "mobile apps," information that was previously handwritten, such as "daily reports," "inventory management," and "stocktaking," can be instantly digitized.

-

"Palette Management System" Information Flyer (Explanation on 2 Pages)

By simply reading the "QR label" on the pallet with a terminal during shipping/return, pallet management can be systematized. With a simple configuration of terminals, PCs, and QR labels, it is possible to build a flexible and highly expandable system for 1. shipping/return management, 2. label issuance operations, and 3. set management with cargo. * Please consult us regarding compatibility with "RFID tags," "Excel," and the use of terminals for "other operations." * We can accommodate "handheld terminals from various companies." Please consult us. * "QR code" is a registered trademark of Denso Wave Incorporated. 【Features / Benefits】 ■ The operational image is a "standard specification." We can accommodate adjustments to fit your operational environment and business procedures. ■ You can start with one operation/device. ■ Please let us know your requests via email. (Web system meetings are also possible.)

-

"Success Stories of 'DX' in Manufacturing Sites (v2.0.0)" - Featuring DX examples that lead to improved competitiveness. Various solutions are also introduced.

In this document, you can see examples of companies that have successfully promoted DX in manufacturing sites through our solutions. "While the digitalization of 'machine' information, such as the introduction of IoT and M2M, is progressing, the 'human' work information remains analog..." "I want to promote DX, but I don't know where to start..." If you have such concerns, please take a look. [Featured Cases] ■ Material Warehouse Management: Reduced labor hours by 4 person-days through paperless operations and improved efficiency in locating materials. ■ Work Progress and Daily Report Management: Reduced 90 hours per month through the digitalization of work information. ■ Maintenance Management: Reduced 20 hours per month through digital management of hygiene control and inspection records. ■ Pallet Management: Reduced losses of 2 million yen per year through data management of shipping destinations and unreturned pallets. *You can view detailed case information immediately by downloading the PDF. Feel free to contact us with any inquiries.

-

A must-see for those aiming for optimal inventory levels, a flexible "inventory management system" tailored to the field.

We can solve the challenges in front of you. While covering everything from receiving inspection to storage registration, inventory management, and shipping management, there is no need to implement all operations from the start. We propose a flexible system that allows you to begin with one high-priority operation, assess the implementation effects, and then consider other operations.

-

"Palette management" can be easily performed. We will guide you through both the basics and advanced applications, incorporating specific operational examples.

You can immediately find out where the "pallet" is located. By using features such as "shipment destination management" and "list of unreturned items," we can prevent the loss of pallets. Additionally, by managing the items loaded on the pallets (such as jigs, molds, containers, etc.) together, you can quickly identify the "shipment destination (storage area)" even when moving pallets, freeing you from the task of searching for them. We are also flexible in accommodating individual requests. Please feel free to contact us.