Axia for Semiconductor Manufacturing: High Hardness and High Strength Stainless Steel

For precision components in semiconductor manufacturing. Achieving high hardness, high strength, and high corrosion resistance.

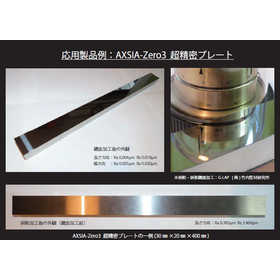

In the semiconductor manufacturing industry, there is a demand for the longevity and stable performance of precision components. Particularly for parts that require high precision machining or are used in harsh environments, wear resistance, corrosion resistance, and strength are crucial. Traditional stainless steel has faced challenges in achieving a balance between hardness and corrosion resistance. Axsia addresses these issues by achieving high hardness of 56-58 HRC, high corrosion resistance equivalent to austenitic grades, and high strength of 2000 MPa class. 【Application Scenarios】 - Precision components for semiconductor manufacturing equipment - Parts requiring high precision machining - Components used in harsh environments 【Benefits of Implementation】 - Extended lifespan of components - Stable operation of equipment - Reduction of total costs

basic information

**Features** - High hardness of 56–58 HRC - High corrosion resistance equivalent to austenitic grades - Achieves high strength of 2000 MPa class - High hardness can be achieved at tempering temperatures (precipitation hardening treatment at approximately 480°C) - Minimal thermal deformation and dimensional changes **Our Strengths** Silicoloy Lab engages in the technological development, research and development, and sales of special stainless steel. We provide comprehensive total support from material sales to heat treatment and processing, assisting our customers in their development.

Price range

Delivery Time

Model number/Brand name

Axia Zero Series

Applications/Examples of results

In addition to purposes such as forged materials, round bars, and flat bars, we develop powder alloys for MIM and alloys for precision casting. *For more details, please contact us.

catalog(1)

Download All CatalogsRecommended products

Distributors

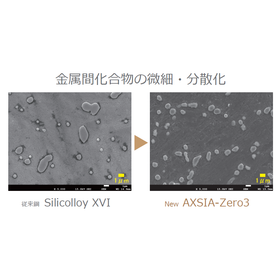

Silicolloy is a revolutionary new material that contains a large amount of silicon (silicon) and was developed using pure domestic technology. Silicolloy is a super alloy that possesses high strength, heat resistance (high-temperature oxidation resistance), corrosion resistance, wear resistance, high hardness, and low dimensional changes during heat treatment, all in one steel. Currently, many engineers (technicians and designers) are advancing its commercialization, contributing to new product development and total cost reduction through extended product lifespan. There are 'Silicolloy A2', which excels in overall balance as a precipitation-hardened stainless steel, and 'Silicolloy XVI', which has the highest hardness in the world as a precipitation-hardened type. Those who require both corrosion resistance and high hardness should definitely take note! In 2025, a new material called 'Axia Zero Series' will be developed. This new material is a precipitation-hardened stainless steel that not only has high corrosion resistance and high hardness but also high strength and high durability. 'Axia Zero3' achieves high hardness of 56-58 HRC, high corrosion resistance equivalent to austenitic types, and high strength in the 2000 MPa range. It features hardness obtained through precipitation hardening treatment at 480°C, which minimizes deformation and dimensional changes due to heat treatment and resolves various issues related to quenching.