Taiyo Technorex Co., Ltd. Company Profile

This is the company profile of Taiyo Technorex. (Company name change effective December 21, 2023)

Taiyo Industrial Co., Ltd. (Established December 1960) Taiyo Technolex Co., Ltd. (Name changed December 2023) [Thoughts Behind the New Company Name] The coined term "TECHNOLEX," derived from "Technology" and "Flexible," symbolizes the flexibility of our main product, FPC (Flexible Printed Circuit Board), as well as our commitment to adapt flexibly not only to conventional technologies but also to new technologies and areas such as technology trading. We are evolving beyond the confines of "industry" and looking towards a transition to a more global market.

basic information

Full support from FPC design, prototyping, and mass production to board electrical testing, appearance inspection systems, and FA automation! TAIYO FPC SOLUTIONS! Taiyo Industry Co., Ltd. continues to operate in the fields of flexible printed circuit board (FPC) prototyping, development, and printed circuit board testing systems. Since FPCs are fundamentally related to the hardware structure, both high precision quality and shortened development time are required. We have extensive experience and know-how in the manufacturing processes of single-sided FPCs, double-sided FPCs, multilayer FPCs, and their advanced types, continuously improving and enhancing our technology, resulting in consistent evaluations for both delivery times and quality. Additionally, while technically advancing further miniaturization and high density, we are also undertaking new initiatives such as bump-type and special material electroplating. On the other hand, our printed circuit board testing systems primarily deploy electrical testing systems and final appearance inspection systems, which are adopted in the mass production sites of FPCs and package/module type boards. They operate day and night in the quality control of boards used in smartphones, automotive applications, and various electronic devices. We never cease our development efforts to meet the increasingly diverse market needs.

Price information

-

Delivery Time

Model number/Brand name

-

Applications/Examples of results

Electronic Circuit Board Business [FPC, Electroforming] Test System Business [TY-CHECKER, TY-VISION] Industrial Machinery System Business [Trading Companies, System Integrators] Mirror Inspection Machine Business [Mirak Co., Ltd.: Cylindrical Mirror Grinding Machine]

catalog(5)

Download All CatalogsNews about this product(3)

-

[Press Release from Taiyo Techno Rex] Announcement regarding the launch of electronic device contract manufacturing services.

We have newly launched an "Electronics Manufacturing Services (EMS)" that provides a comprehensive response from material procurement, circuit design, manufacturing, and assembly to functional testing and shipping in the traditional FPC (Flexible Printed Circuit Board) manufacturing process. In recent years, the use of FPCs has expanded across various fields such as medical devices and industrial equipment, leading to an increased demand not only for supply but also for a one-stop solution that encompasses circuit design, module manufacturing, and even final product assembly. To meet these market demands, we have strengthened our collaboration with electronics manufacturing companies and established a manufacturing system that covers everything from material procurement to assembly. With this service, customers can reduce interactions with multiple vendors, achieve shorter lead times, and improve manufacturing efficiency. Our stringent quality control system ensures the delivery of highly reliable products. The product areas we can support include automotive devices, medical devices, industrial equipment, robotics, communication devices, lighting equipment, and home appliances, allowing us to meet a wide range of manufacturing needs.

-

[Press Release from Taiyo TechnoRex] Regarding the Improvement of High-Density Wiring Formation Technology Using the Patterned Beer Fill Method

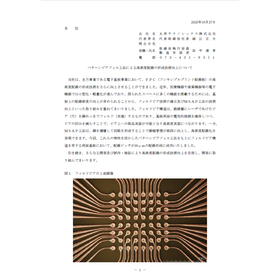

Our company has further improved the technology for forming high-density wiring in our core business of electronic substrates, specifically in flexible printed circuit boards (FPCs). In recent years, electronic devices such as medical equipment and industrial machinery have been advancing in miniaturization and lightweight design. To incorporate many functions into limited space, there is a demand for increased wiring density on the substrate. Therefore, we have been working on establishing filled via technology and improving the M-SAP method. The filled via structure involves filling vias (holes) made by laser in the insulating layer with copper plating, ensuring electrical connections on both sides of the substrate while reducing the recesses of the vias, which allows for component mounting on the vias and leads to high-density mounting. On the other hand, the M-SAP method significantly improves line width management by laminating copper to form circuits, enabling high-density wiring. This time, based on the pattern via fill method that leverages these characteristics, we successfully formed wiring with a pitch of 30μm on a double-sided substrate with a filled via structure. We will continue to aim for further improvements in high-density wiring formation technology through ongoing development, prototyping, and verification.

-

Press Release from Taiyo TechnoRex: Participation in Wakayama Prefecture's "Space Town Development Promotion Project"

Our company has decided to participate in the "Space Town Development Promotion Project (Kii Space HUB)," which aims to create new industries and revitalize the region with a space theme, promoted by Wakayama Prefecture, in our core business of electronic substrate. Taking this opportunity, we will actively advance our technological development and business enhancement in the space field. The Space Town Development Promotion Project is a project aimed at the accumulation of the space industry, human resource development, and regional revitalization in Wakayama Prefecture, where the private rocket launch site "Spaceport Kii" is located, and it has garnered national attention. We aim to contribute to the lightweight and high functionality of space equipment by leveraging the manufacturing technologies of flexible printed circuit boards and electroforming that we have cultivated so far. In the future, we will actively engage in human resource development for those involved in the space business, starting with the provision of technology for satellite-mounted equipment and communication modules. We will also consider collaboration with private space companies, promoting value creation and business development in this new field of the space industry, while striving to balance technological innovation and social contribution, and continuing our challenges toward realizing a sustainable future.

Recommended products

Distributors

Taiyo TechnoRex Co., Ltd. continues to operate in the fields of prototype development of flexible printed circuit boards (FPC) and printed circuit board testing systems. Since FPC is fundamentally related to the structure of hardware, both high precision quality and shortened development time are required. We have extensive experience and know-how in the manufacturing processes of single-sided FPC, double-sided FPC, multilayer FPC, and their advanced types, and we continuously improve and enhance our technology, resulting in consistent evaluations of our delivery times and quality. Additionally, while technically advancing further miniaturization and high density, we are also undertaking new initiatives such as bump-type and special material electroplating. On the other hand, our printed circuit board testing systems mainly consist of electrical inspection systems and final appearance inspection systems, which are adopted in the mass production sites of FPCs and package/module-type substrates. They operate day and night in quality control settings for substrates used in smartphones, automotive applications, and various electronic devices. We will continue to respond to the increasingly diverse market needs. *On December 21, 2023, the company name was changed from "Taiyo Kogyo Co., Ltd." to "Taiyo TechnoRex Co., Ltd."*