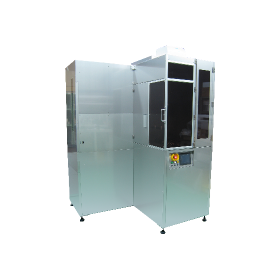

Film Attachment Device | Semi-Automatic Mounter "FM-903S"

Semi-automatic tabletop type wafer mounter for up to 8 inches.

The operator will only handle the setting and removal of the work, and all subsequent tasks will be fully automated. This will contribute to the stability of the tape/film application process and improve yield.

basic information

■Features - Automatic attachment and auto film cutting mechanism. - Variable attachment pressure. - Variable attachment speed. - Automatic balance function for attachment rollers. - Options: heater unit, static electricity countermeasures. - Tabletop type. ■Benefits The main benefits of introducing a wafer mounter include "stable attachment quality," "speedy manufacturing operations," and "prevention of chip flying." By fully utilizing these features, an increase in productivity due to high yield can be expected. The operator simply needs to set the wafer and frame and press start.

Price range

Delivery Time

Model number/Brand name

FM-903S

Applications/Examples of results

A device for attaching "wafers," "dicing frames," and "various tapes." ■ Applications: 【Dicing Applications】 After dicing the wafer with a dicer, dicing tape is attached to the back side to hold the wafer being cut during dicing, preventing the chips from scattering. 【Protection (Back Grind/BG) Applications】 When performing back grinding on the backside of the wafer for thinning purposes, protective tape is attached to protect the circuits on the surface. 【Others】 It is also possible to accommodate other roll-type films for film attachment (such as DAF attachment, resist film attachment, etc.).

Related Videos

Line up(1)

| Model number | overview |

|---|---|

| FM-903S | Wafer size: up to 8 inches, equipment dimensions: 1,000mm (W) x 600mm (D) x 800mm (H) |

catalog(2)

Download All CatalogsRecommended products

Distributors

Techno Vision Co., Ltd. has been engaged in the development, manufacturing, and import/export of its own products, focusing on cleaning technology and assembly technology since its establishment in September 1987. In today's high-tech industry, we are committed to responding to our customers' needs and providing technology, products, and services from the perspective of our customers.