news list

latest news

Notice of Year-End and New Year Holidays and Final Shipping Date for 2025

Thank you very much for your continued support. We will be on winter vacation from December 28, 2025 (Saturday) to January 4, 2026 (Sunday). The last shipping date will be until 2:00 PM on December 25…

271~300 item / All 339 items

-

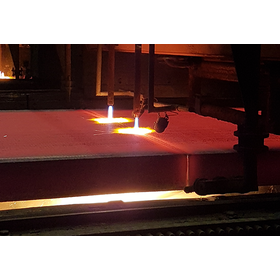

Delivery of LOTZ (Germany) manufactured torch cutting equipment.

LOTZ Cutting has recently delivered gas cutting equipment (torch cutting) to HKM (Krupp Mannesmann) in Duisburg, Germany. Having become independent from the former GEGA LOTZ, LOTZ Cutting now handles not only gas cutting equipment but also consumables from the former GEGA LOTZ. As GEGA LOTZ, we have various achievements in Japan, and as a manufacturer, we are experiencing remarkable growth in Germany in terms of experience, history, and personnel. If you have any inquiries regarding LOTZ products, please contact our staff.

-

Lechler's vertical axis full cone nozzle Japanese catalog is now available.

Published is the Japanese text regarding the patented vertical-axis full cone nozzle manufactured by Rehira. Compared to conventional full cone nozzles, the maximum foreign object passage diameter has increased by 30% to 40%, significantly improving clogging caused by foreign objects. Additionally, the spray angle remains constant even when spraying at different pressures.

-

Lechler spray nozzle video update

We have received the latest video from Lechler GmbH. https://www.youtube.com/channel/UCh7EJGsTjLVISt7D5QmCYCg/featured The functions corresponding to the shapes of each spray nozzle have been made clearer. Additionally, we have also included promotional videos for agricultural spray nozzles and accessories, not just industrial spray nozzles. We have a wide range of spray nozzles and accessories for drones, which have been gaining attention recently. If you have any questions, please feel free to contact our staff. Best regards, The Sales Team

-

Notice of Year-End and New Year Holidays

Thank you for your continued support. Our year-end and New Year holiday schedule is as follows: From Saturday, December 29, 2018, to Sunday, January 6, 2019. *Please note that shipments will be accepted until 3:00 PM on December 26. We appreciate your understanding.

-

We have joined the Exhaust Gas Cleaning Systems Association.

This association was established by members for the development and design of exhaust gas cleaning systems for ships, in order to comply with exhaust gas regulations. Rehila, as a global nozzle manufacturer, will leverage its past achievements and experience to provide the latest technology as exhaust gas regulations for ships are strengthened.

-

Thank you for visiting the 2018 Cleaning Comprehensive Exhibition.

We would like to express our heartfelt gratitude to all the customers who visited our booth at the 2018 Cleaning Comprehensive Exhibition held at Tokyo Big Sight from October 17 to 19, 2018. We understand that there may have been some shortcomings due to the limited time for explanations. If you have any questions or inquiries regarding our products, please feel free to contact us. We look forward to your continued support. Tick Corporation Co., Ltd.

-

Lechler tank cleaning nozzle (general) Japanese version distribution has started.

We have started distributing the Japanese version of the catalog for the Lehira tank cleaning nozzles (comprehensive). Tank cleaning nozzles are essential for a wide variety of applications, ranging from traditional spray balls to gear-type tank cleaning. Additionally, as our products are certified by European standards, FDA, and 3A, they fully comply with the requirements of food sanitation laws. If you have any questions or inquiries regarding this product, please feel free to contact our staff.

-

Notice of Participation in the 2018 Cleaning Comprehensive Exhibition

We will be exhibiting the Sonic Corporation's blower and air knife system (water removal/drying equipment) at the 2018 Cleaning Comprehensive Exhibition. Water removal/drying is still an eternal theme. It is not possible to achieve effective water removal/drying with a low-capacity blower. What is needed for water removal/drying is a large airflow. Additionally, an air knife that efficiently blows out that large airflow is also necessary. Furthermore, controlling it is very simple if you use a vortex blower. The products we plan to exhibit are: - Sonic Model 85 (with soundproof box) blower - XE air knife (standard model) - Rotary air knife (patented) - Other peripheral equipment We invite you to visit our booth during this opportunity. If you need an invitation, please contact our sales staff.

-

Start of sales for Lechler's tank cleaning spray nozzle RinseClean (model number: 5B2/5B3).

RinseClean is used in places where high temperatures are required and for applications that demand a very high level of sanitation (High Hygienic). It is now possible to achieve higher flow rates and spraying, and the selection range for fixed spray balls has become wider.

-

Notice of Summer Vacation

We would like to inform you about our summer holiday schedule. We apologize for any inconvenience this may cause and appreciate your understanding. From August 13 (Monday) to August 15 (Wednesday) Partial operations from August 16 (Thursday) Regular operations resume on August 20 (Monday) *Shipping will also resume on the 20th.

-

[Sonic] DRY-IN-PLACE (Tank Dryer) Product Catalog Listing

A tank dryer that utilizes heat emitted from a blower to dry the interior of the tank. By promoting the drying of the tank, it can shorten the time for reactivation and reuse after CIP (Clean-in-Place). As a result, it can shorten the manufacturing process, making it a groundbreaking product that contributes to energy savings.

-

Comprehensive catalog listing of LOTZ Corporation's torch cutting equipment.

An independent German torch cutting equipment manufacturer that was formerly part of GEGA LOTZ (now Alpine Metal Tech). They provide everything from the latest equipment to replacement parts for older models.

-

Catalog listing for Lechler mist separator (demister).

Catalog listing of mist separators manufactured by the German spray nozzle maker Lechler GmbH. They are now capable of handling a wide range of applications from plastic materials to stainless steel.

-

Notice of Year-End and New Year Holidays

We would like to inform you about our year-end and New Year holiday schedule. From December 30, 2017 (Saturday) to January 8, 2018 (Monday). *Business (shipping) will be available until the morning of December 28. Thank you for your understanding.

-

[Important] Notice of Shipping Fee Revision

In the season of December, I would like to congratulate you on the continued prosperity of your company. I sincerely appreciate your exceptional support as always. We would like to inform you that starting from orders placed on January 1, 2018, we will be revising our shipping fees. Since October 2017, there have been successive price revisions by various shipping companies, resulting in a very difficult situation that exceeds our cost base. We sincerely ask for your understanding regarding this difficult decision. After the revision, for domestic shipping costs, if the purchase amount is 20,000 yen or less (excluding tax), a shipping fee of 1,500 yen (excluding tax) will be charged separately. (This excludes islands such as Okinawa and Yakushima.) Additionally, please note that if there are specific time requests, additional charges may apply. Tick Corporation, President Hisashi Tanaka

-

Start of import and sales of Lechler mist separators (demisters).

Rehilar's mist separator (demister) is used in over 100 applications across various industries. Supply Range: Regarding the requirements for gas-water separation technology, we can provide single or multiple stage systems for vertical and horizontal gas flow directions: - Horizontal or vertical gas flow vane-type mist separators - Vane-type mist separators with housing - Vane-type mist separators designed with pressure vessels compliant with PED 97/23/EC, AD 2000, ASME, or other special regulations - Spin vane separators - Inlet distributors (inlet distribution equipment) - Vane-type mist separators combined with condensate units or oil-water separation treatment devices - Flow systems for cleaning mist separators - CFD technology to improve the functionality of mist separator systems Materials: - PP, PVDF, PE - Stainless steel (AISI304, AISI304L, AISI316L, AISI316Ti) * Upon request: Duplex, SMO254, Ni201, alloys, or Hastelloy

-

Start of handling and sales of the German Lotz company’s torch cutting equipment.

Lotz is a manufacturer that primarily produces and sells gas cutting equipment (torch cutting) for the steel industry, having become independent from the former GEGA LOTZ (now ALPINE METAL TECH (GEGA)) in 2014. Products handled: - Blooms and billets - Gas cutting equipment for continuous casting of slabs (torch cutting) - Burr removal equipment - Width splitting equipment - Consumable nozzles/parts and more If you have any questions, please feel free to contact our staff.

-

Start of handling and sales of GESSMANN (Gessmann) plastic connectors from Germany.

GESSMANN is a manufacturer of high-quality plastic connectors for the automotive and semiconductor industries. If you have any questions, please feel free to contact our staff.

-

Notice of Summer Vacation

We would like to inform you about our summer holiday schedule. We sincerely apologize for any inconvenience this may cause and appreciate your understanding. From August 11 (Friday) to August 16 (Wednesday) Regular business will resume on August 17 (Thursday).

-

Lechler tank cleaning spray nozzle [Quick reference table] available for download.

In industries that require tank cleaning, there are nozzles that cannot be used unless they meet various strict conditions. For example: - 3A Sanitary Standards - EHEDG (European Hygienic Engineering and Design Group) - FDA (U.S. Food and Drug Administration) - Regulation (EC) No. 1935/2004 - ATEX Directive (Explosion Protection) As mentioned above, regulations in Europe and the United States are very strictly managed. The German manufacturer Lechler GmbH supplies nozzles that comply with these standards. This one-page flyer provides a simple and easy-to-understand explanation of which nozzles conform to which standards. Please make use of it when selecting spray nozzles for tank cleaning.

-

Lechler Tank Clean Software

There are many industries that use tanks in their manufacturing processes. The tanks used in those production lines must be cleaned. Recently, there are various cleaning methods available, but Lehira Corporation has developed a tank cleaning nozzle focusing particularly on the keyword "mechanical parts" among the four keywords: "temperature, cleaning time, chemical agents, and mechanical parts." Based on our achievements and experience, we have developed new software. If you could provide us with the shape of the actual tank at your company, we can input that information into the software and select the appropriate tank cleaning nozzle. As a result, we can confirm the cleaning effectiveness and efficiency within the tank before conducting the actual operation. Until now, the cleaning effectiveness of the actual tank was only visually assessed using demo units, without precise measurements. However, with the development of this software, we can identify areas where the cleaning solution does not reach, areas that are not hit by the spray from the nozzle, and areas that receive neither the cleaning solution nor the spray, allowing us to select the most suitable tank cleaning nozzle. By using the appropriate tank cleaning nozzle, we can reduce cleaning time, minimize the amount of liquid used, and shorten the time until the next manufacturing process, which in turn contributes to energy savings.

-

Start of distribution for the leaflet on Lechler tank cleaning spray nozzles.

The distribution of the leaflet for the Lehira company's tank cleaning spray nozzle has begun. This spray nozzle is highly efficient in cleaning and is also energy-saving. The operating pressure is low, ranging from approximately 0.1 MPa to 1 MPa, but the unique spray pattern and method developed by Lehira enhance cleaning efficiency, making it suitable for energy savings, reduction of cleaning solution, and shortening of cleaning time. Types: We offer a wide variety of tank cleaning nozzles in different types and materials to meet all applications. Therefore, you can select the most suitable nozzle and material from among them. The target tank sizes range from 1m to 16m, including fixed installations and transport tanks such as tank trucks. Additionally, we have received approval for various food and medical standards. Advantages: - A comprehensive product range allows for the selection of tank cleaning nozzles for both small and large tanks. - By avoiding the dangers associated with tank cleaning, it is possible to reduce labor costs. - A cleaning method that utilizes the "coarseness of particle size" unique to low-pressure nozzles (excluding straight nozzles). - Nozzles developed from over 25,000 types and more than 130 years of experience. For any questions, please contact our staff.

-

Sales of Sonic SMART TUNNEL for Sonic Corporation's air knife have begun.

We have started selling the modular SMART TUNNEL, which can suppress the splashing of water generated during the inspection, printing, labeling, and water draining/drying of filled PET bottles, cans, bottles, and pouches before packaging. Traditional splash prevention boxes were very costly due to custom orders and had a very complicated installation process. This SMART TUNNEL is easy to install on existing conveyors and is compact. We have posted a video on YouTube showing the installation method. Please take a look, and if you have any questions, feel free to contact our staff.

-

Notice of Year-End and New Year Holidays

We will be closed for the New Year holiday from Thursday, December 29, 2016, to Wednesday, January 4, 2017. Please note that shipments will be made until the morning of December 27. Thank you for your understanding.

-

Thank you for visiting the Sonic Cleaning Comprehensive Exhibition.

Thank you very much for visiting our booth at the 2016 Cleaning Comprehensive Exhibition held at Tokyo Big Sight the other day. We apologize for not being able to provide satisfactory assistance in the short time available. If you have any concerns or questions regarding water drainage, drying, blowing off, etc., after cleaning, please feel free to contact our staff. We look forward to your continued support. Tick Corporation, All staff

-

The catalog for the ultrasonic spray nozzle has been updated!

The catalog for the ultrasonic spray nozzle has been updated. The latest catalog was published in October 2016. The catalog is already available for viewing, so please feel free to use it. If you have any questions about the products, please do not hesitate to contact us.

-

The catalog for the tank cleaning nozzle has been updated!

The catalog for the Lehira company's tank cleaning nozzles has been updated! It is now more detailed and has a more user-friendly layout compared to the previous version. Please take this opportunity to take a look. If you have any questions about the products, feel free to contact us.

-

Notice of Model Number Change for Ultrasonic Spray Nozzle

Thank you very much for using our products. We would like to inform you that the model numbers for the Sonaer ultrasonic spray nozzles have been changed as follows. Wide Spray Old Model Number New Model Number ・20K50ST → WS20K50 ・40K50ST → WS40K50 ・60K50ST → WS60K50 ・130K50ST → WS130K50 Narrow Spray Old Model Number New Model Number ・40K50T → NS40K50 ・60K50T → NS60K50 ・130K50T → NS130K50 Radial Spray Old Model Number New Model Number ・CF40K50T → CF40K50 There are no changes to the specifications of the products due to the model number change. The product catalog has already been updated accordingly. If you have any questions, please feel free to contact us. We appreciate your continued support.

-

We will be exhibiting Sonic Corporation's blowers and air knives (water removal/drying equipment) at the 2016 Cleaning Comprehensive Exhibition.

We will be exhibiting the Sonic Corporation's blower and air knife system (water removal/drying equipment) at the 2016 Cleaning Comprehensive Exhibition. Booth Number: W58 Water removal/drying is still an eternal theme. Using a low-capacity blower will not achieve effective water removal/drying. What is needed for water removal/drying is a large airflow. Additionally, an air knife that efficiently emits that large airflow is also necessary. Furthermore, controlling it is very simple if using a scroll-type blower. The products we plan to exhibit are: - Sonic Model 85 (with soundproof enclosure) blower - Knozzle (patented) - Rotary air knife (patented) - XE air knife and other peripheral equipment Please take this opportunity to visit our booth. If you need an invitation, please contact our sales staff. *We will inform you of the booth details as soon as they are available.

-

Start of distribution for the new leaflet of Lechler Multi-Channel Jet (Air Nozzle) FL-600E.

Did you know? The only air nozzle in the world that can be equipped with an orifice cover is the Rehira FL-600E. The best-selling multi-channel jet FL-600E comes with an orifice cover as an accessory. By using this orifice cover, you can block unnecessary holes in the air nozzle. It is used for areas where blowing is unnecessary and for changing the airflow. By blocking the holes in the air nozzle, you can achieve greater energy savings. The orifice cover that comes with the multi-channel jet FL-600E can also be used with its sister products, the FL-600S, FL-600PP, and FL-600H. *Please note that the orifice cover is not included with the purchase of the above three types. You can download the leaflet from the catalog request. If you have any inquiries regarding the product, please contact our staff. Tick Corporation Co., Ltd. Sales Staff