Composite repair

Composite repair

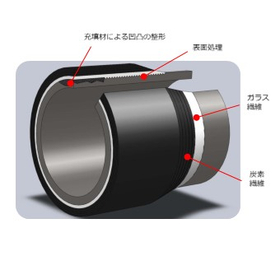

This is a service for the restoration of strength and leak prevention of piping using carbon fiber composites.

1~15 item / All 15 items

-

Long-term extension of meat reduction piping with 'Composite Repair' *Presentation of construction case materials

Repairs are made according to the necessary durability years and purpose (strength restoration, leak prevention, corrosion protection). It allows for predicting maintenance timing and is suitable for permanent plant maintenance!

last updated

-

【Basic Knowledge Material】What is Composite Repair?

We introduce the design, quality, and history of the development of composite repairs!

last updated

-

【Basic Knowledge Material】Corrosion Prevention and Leak Sealing! What are the Effects of Composite Repair?

We are publishing examples of composite repairs that not only provide corrosion protection but also have leak-stopping effects!

last updated

-

【Basic Knowledge Material】How strong is composite repair?

We have published examples that verify how much strength can be restored with composite repair!

last updated

-

[Basic Knowledge Material] What are the methods to extend the lifespan of reduced meat plant piping?

Extend the lifespan of plant piping that has been reduced in thickness due to external corrosion! We propose a new option that differs from simple measures such as repainting, FRP wrapping, and iron cement coating.

last updated

-

[Basic Knowledge Material] A Thorough Explanation of the Strength Calculation Method for Composite Repairs!

Choose the appropriate calculation formula from multiple patterns! Introducing the concept of strength calculation.

last updated

-

[Composite Repair Case Study] Repairing Pipe Thickness Without Stopping the Plant!

Restoration of strength, leak prevention, and corrosion protection effects of reduced meat piping! Case studies of composite repair services.

last updated

-

[Composite Repair Case Study] Repair of Pipe Corrosion and Thinning Due to Rainwater

Composite materials of carbon fiber and epoxy resin for leak sealing and corrosion prevention in reduced thickness piping. *Examples of application in petroleum refining plants are introduced.

last updated

-

[Composite Repair Case Study] Fire Hydrant Reduced Thickness Pipe Penetration and Leak Repair

Composite materials made of carbon fiber and epoxy resin to avoid the risk of pipe bursts and unexpected shutdowns at power plants! *Examples of construction at thermal power plants are introduced with photos.

last updated

-

【Basic Knowledge Material】What are carbon fiber composites necessary for pipe repair?

Widely used as materials for sports applications, as well as for aircraft and automobile bodies!

last updated

-

Basic Knowledge Material: What is the epoxy resin needed for pipe repair?

You can change the properties by adding additives to the hardener!

last updated

-

Thorough verification of leak prevention performance of stainless steel piping using composite repair.

Not only carbon steel, but also stainless steel piping can be installed! Verification of leak prevention effectiveness.

last updated

-

Thorough verification of leak prevention performance under harsh construction conditions using composite repair.

We offer services that can be expected to restore the strength of reduced meat piping, stop leaks, and improve textile effects!

last updated

-

Verification of leak prevention performance when repairing through holes with composite repair.

If you can remove the contents, it is possible to stop the leak with composite repair!

last updated

-

What is the appropriate corrosion and thinning prevention maintenance for the contact points between piping and supports?

We propose a composite repair aimed at achieving corrosion protection by stacking a minimum of two layers in the area to be protected!

last updated