【コンポジットリペア施工事例】プラント停止せずに配管肉厚を補修!

減肉配管の強度復元・漏れ止め・防食の効果!コンポジットリペアサービスの事例

石油精製プラント内タンクの上部に敷設された8B配管に腐食が発生し、 RT結果によると、3/4Bボス部分の最小肉厚が0.6mmであると判明しました。 万が一配管に不具合が発生すると、内部流体(ブタン)の漏洩の恐れがあり、 配管更新をするにはプラント全体を停止しなければならず、漏洩発生する前の 防食対策が必須でした。 そこでボス部分を中心として、8B母管の左右300mmの範囲の防食として コンポジットを2層積層。 コンポジット層の高い環境遮断効果により、外部腐食の進行を完全に防止し、 防食塗単独による対策よりも漏洩発生のリスクを低減できます。 【効果】 ■コンポジット層の高い環境遮断効果により、外部腐食の進行を完全に防止 ■防食塗単独による対策よりも漏洩発生のリスクを低減できる ※詳しくはPDF資料をご覧いただくか、お気軽にお問い合わせ下さい。

基本情報

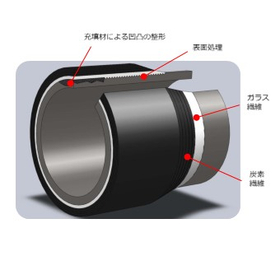

【事例概要】 ■対策 ・ボス部分を中心として、8B母管の左右300mmの範囲の防食としてコンポジットを2層積層 ■施工(2名×2日間) ・整形 ・表面処理 ・ガラス繊維と炭素繊維を積層 ・硬化確認 ■施工ポイント ・炭素繊維は鉄の約4分の1の重さにもかかわらず、強度は約10倍、硬さは約7倍で、 “軽くて丈夫”という優れた特長を持つ素材 ・資機材の搬入が容易なだけでなく、高所に敷設された減肉した配管(サポートなし)に 積層しても、軽量のため荷重がかかる心配も不要 ※詳しくはPDF資料をご覧いただくか、お気軽にお問い合わせ下さい。

価格帯

納期

用途/実績例

※詳しくはPDF資料をご覧いただくか、お気軽にお問い合わせ下さい。

カタログ(9)

カタログをまとめてダウンロードおすすめ製品

取り扱い会社

富士ファーマナイトは、1978年に富士電機工事株式会社(現・富士電機E&C株式会社)とイギリスのファーマナイト社との合弁により、漏洩補修の専門会社として発足しました。 ファーマナイトが提供する【リークシール】は、熱源や動力源および製品製造過程における各種流体(スチーム、空気、油、ガス等)の漏洩に対応しており、さまざまな産業分野で幅広くご利用いただいております。 プラントメンテナンスの観点から、減肉配管の強度復元を目的とした【コンポジットリペア】、振動により固着弁を開放する【ファーマイーズ】等の新しいサービスも開始しました。 当社の優れた技術員が、イギリスのファーマナイト社独自の技術を高品質でご提供します。