Composite Repair Case Study (Oil Refining)

Composite Repair Case Study (Oil Refining)

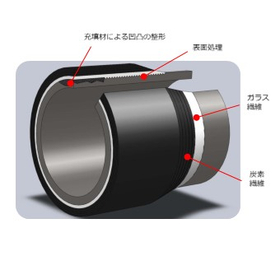

The underside of the piping has extensive wall thinning, and it was absolutely necessary to prevent any leakage from the piping until it could be replaced during the next scheduled maintenance. Since this is within a refinery, reinforcement with welded steel plates could not be performed. Additionally, stopping the equipment would incur enormous costs, so we adopted our composite repair. According to strength calculations, it was determined that even if leakage occurred due to penetration at the thinned areas, complete prevention of leakage could be achieved with five layers of lamination. Since there was a risk of penetration, we did not perform surface preparation at the thinned areas, and instead, we applied composite repair only to the underside of the thinned piping, rather than around the entire circumference of the piping. If the internal fluid pressure is below 0.1 MPa, even in piping with a large diameter and extensive wall thinning, long-term preventive maintenance is possible with the composite layer.

1~4 item / All 4 items

-

Long-term extension of meat reduction piping with 'Composite Repair' *Presentation of construction case materials

Repairs are made according to the necessary durability years and purpose (strength restoration, leak prevention, corrosion protection). It allows for predicting maintenance timing and is suitable for permanent plant maintenance!

last updated

-

【Basic Knowledge Material】What is Composite Repair?

We introduce the design, quality, and history of the development of composite repairs!

last updated

-

[Composite Repair Case Study] Repair of Pipe Corrosion and Thinning Due to Rainwater

Composite materials of carbon fiber and epoxy resin for leak sealing and corrosion prevention in reduced thickness piping. *Examples of application in petroleum refining plants are introduced.

last updated

-

[Composite Repair Case Study] Repairing Pipe Thickness Without Stopping the Plant!

Restoration of strength, leak prevention, and corrosion protection effects of reduced meat piping! Case studies of composite repair services.

last updated